OK, I've got a collection of cordless power tools that use the same batteries - but they are now 11 years old, and the batteries (I have three batteries, and two chargers) are now pretty useless, as you would expect. The tools themselves are perfectly fine.

The batteries are 18V 2AH and use NiMh half-C cells, with the input/output connector spot welded to the top of the batteries themselves.

These are the batteries removed from the casing, the thin brown and black wires got to a diode (I presume it's a diode) as a temperature sensor.

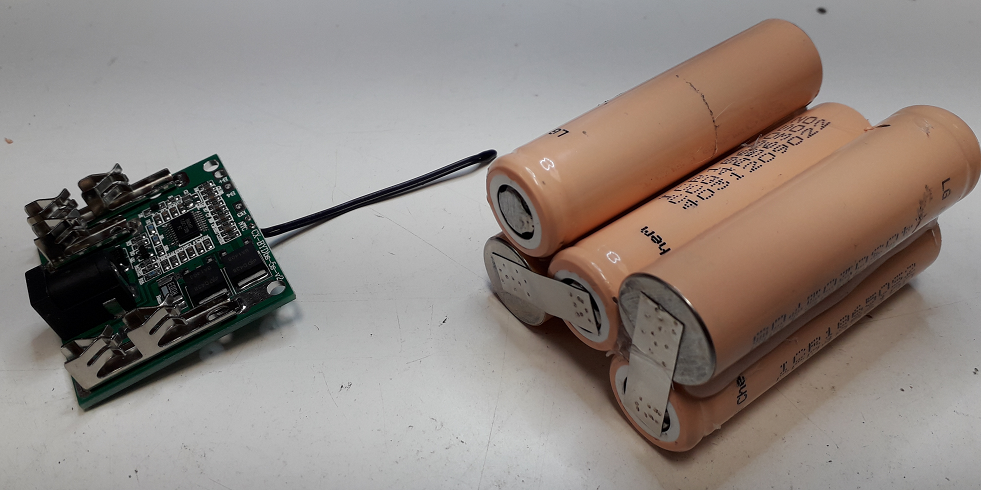

I was considering ordering some replacement half_C cells, but 45 of them is a lot of money, and they still aren't very good batteries. So as I've got a pile of 'rescued' 18650 Li-Ion cells I decided to use those (we replace a LOT of batteries at work, both when they are faulty, and as regular service work on request - so I have a decent supply of them - I can't bear to see them thrown away!). For the 18V I needed 5 cells, and I hoped to be able to squeeze 10 in to double the power - but it was a little tight, so I keep with 5 instead (which incidentally is exactly what our new DeWalt drill at work uses).

So using our battery spot-welder I built them up in a pack of five cells, and ordered some suitable battery protection boards from China.

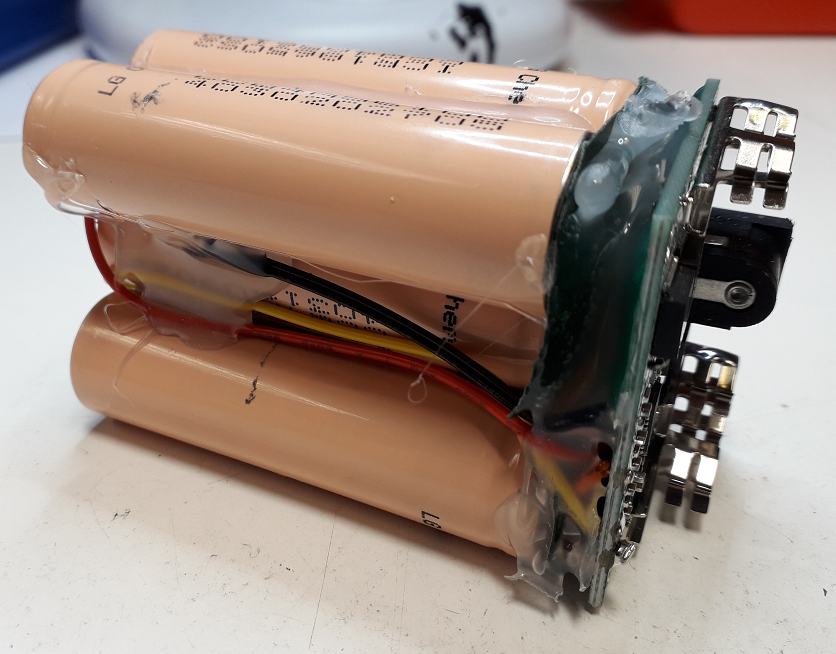

This is a completed battery pack, the black wire you can see is the temperature sensor from the protection board, which is glued to the side of the pack. Plenty of hot melt glue holds everything together.

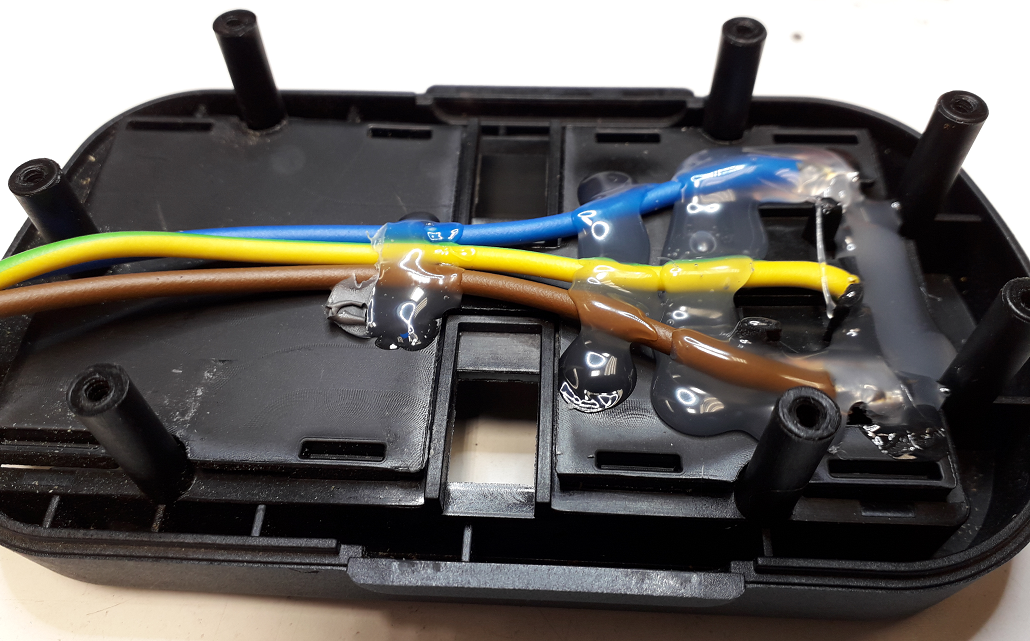

Next was the problem of connections, so I used more hot melt to fasten the original connector in place in the top, and ran thickish wires from that.

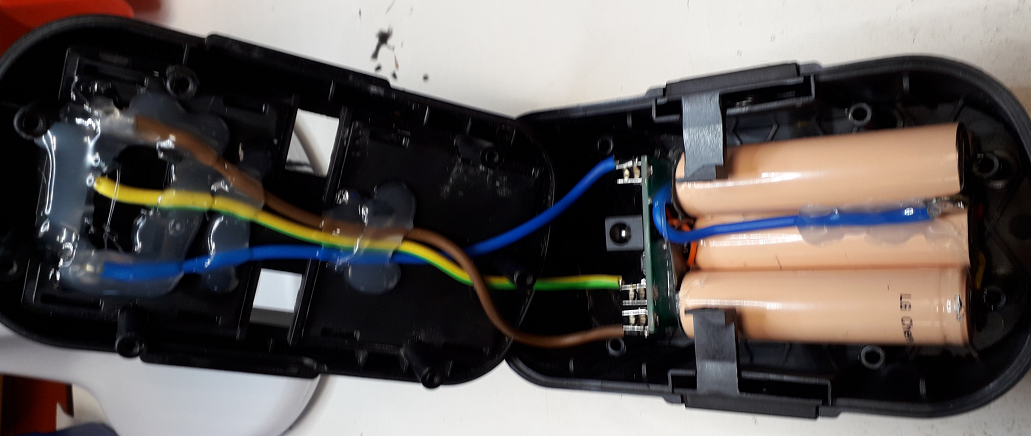

The new battery pack was hot melt glued in the old case.

And the wires from the top soldered in place, to the sides of the metal clips you can see above on the protection board.

So that's the batteries done - next job will be to rebuild the chargers - these use a conventional mains transformer, and an LM324 quad opamp for the charge controller - the new pack has separate charge+ and output+ from the protection board, so I connected the middle pin (used for the original temperature sensor) to the charge+ connection.

I've got some small Chinese charger boards, adjustable constant voltage and constant current, so I'm planning using those, and probably a PIC to monitor charge status - I haven't really decided yet, and I've yet to try charging the packs 'manually' to see what the protection board does as regarded charging (I pre-charged all the cells before building the packs).

Incidentally, the old batteries weighed 1056gm, the new ones only weigh 486gm, so less than half the weight.

Nice little upgrade, the batteries were free, and the protection boards under £2 each.

The batteries are 18V 2AH and use NiMh half-C cells, with the input/output connector spot welded to the top of the batteries themselves.

These are the batteries removed from the casing, the thin brown and black wires got to a diode (I presume it's a diode) as a temperature sensor.

I was considering ordering some replacement half_C cells, but 45 of them is a lot of money, and they still aren't very good batteries. So as I've got a pile of 'rescued' 18650 Li-Ion cells I decided to use those (we replace a LOT of batteries at work, both when they are faulty, and as regular service work on request - so I have a decent supply of them - I can't bear to see them thrown away!). For the 18V I needed 5 cells, and I hoped to be able to squeeze 10 in to double the power - but it was a little tight, so I keep with 5 instead (which incidentally is exactly what our new DeWalt drill at work uses).

So using our battery spot-welder I built them up in a pack of five cells, and ordered some suitable battery protection boards from China.

This is a completed battery pack, the black wire you can see is the temperature sensor from the protection board, which is glued to the side of the pack. Plenty of hot melt glue holds everything together.

Next was the problem of connections, so I used more hot melt to fasten the original connector in place in the top, and ran thickish wires from that.

The new battery pack was hot melt glued in the old case.

And the wires from the top soldered in place, to the sides of the metal clips you can see above on the protection board.

So that's the batteries done - next job will be to rebuild the chargers - these use a conventional mains transformer, and an LM324 quad opamp for the charge controller - the new pack has separate charge+ and output+ from the protection board, so I connected the middle pin (used for the original temperature sensor) to the charge+ connection.

I've got some small Chinese charger boards, adjustable constant voltage and constant current, so I'm planning using those, and probably a PIC to monitor charge status - I haven't really decided yet, and I've yet to try charging the packs 'manually' to see what the protection board does as regarded charging (I pre-charged all the cells before building the packs).

Incidentally, the old batteries weighed 1056gm, the new ones only weigh 486gm, so less than half the weight.

Nice little upgrade, the batteries were free, and the protection boards under £2 each.

Attachments

Last edited: