Danwvw

Active Member

Up Date Yep had to switch back to the 350 which is totally Clean!

ADCMP350 Data Sheet.

LT-6700-1 Data Sheet.

Some Follow-up on the 6700i prototype, Given the success of the 393i prototype later in this thread and the fact that I can't drive my car right now due to the LF brake locked up, I want to revisit the 6700i prototype. It has what I thought was 2 problems however they could be the same thing. When 1st installed in the car the voltage would surge above regulation voltage which I thought I cured with caps across D+ 2nd with a full battery it over charges the battery unless there is some load on the system like the park lights.

Maybe I will start by trying a voltage limiting filter on D+

One idea that I realized after testing D+ ripple on the scope about 1 volt is to simply feedback the Un-Regulated Supply voltage instead of D+ to the LT-6700-1 Inverting input to control voltage. It would be simpler and it clears up the ripple on the feedback.

Well tried the feedback from the Un-Regulated Supply but it still results and some ripple, Now I am thinking of just incorporating the filer idea into the 6.8 volt Zener used to set the voltage but I did try that on the car with slightly improved regulation however I think it's worth playing with and reducing the value of the series resistor to maybe 16 ohms. Bench testing adding a 820uf filter parallel with a 100 ohm resistor resulted in a rapid flashing LED tail light that I used as a generator output load.

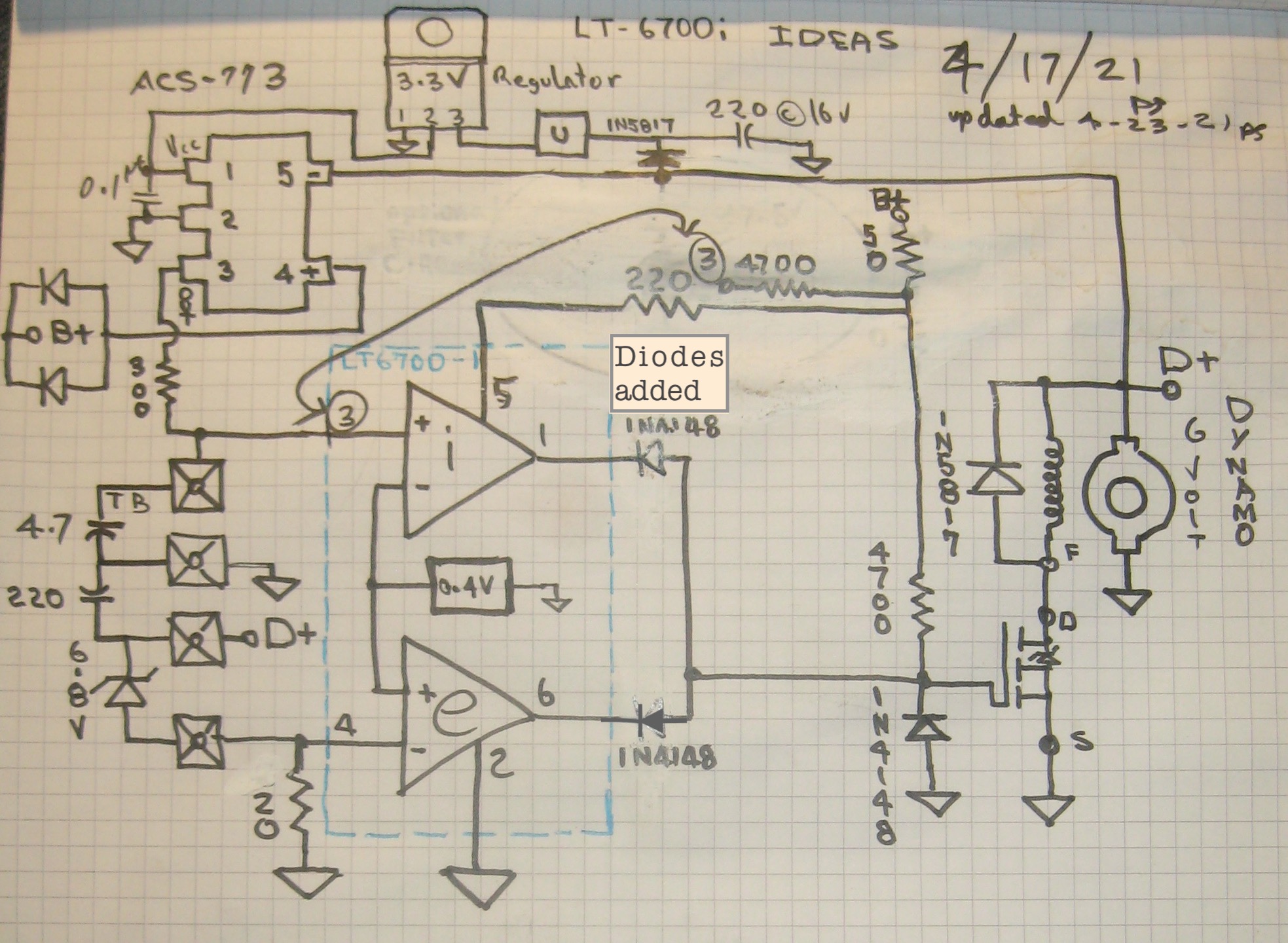

See the Third Schematic below bench test getting 0.28 volts pp ripple at the inv input which is a little improvement, also the D+ output DC regulation when loaded is unchanged something I am pleased with.

April 23, 2021

The 6700i went back on the car today to compare any improvements, Seems a little better, still charges to 7.5 volts at the battery no lights and it is outputting 6.9 Volts at the Regulator with the lights. The 393i was better still. I think what is happening is some noise is triggering the LT-6700 comparator i input, I added a 4.7 uf cap across it to ground it may have helped a little, for now leaving this one on the car for more testing.

Did more testing in the car. definitely too much voltage with the lights off, did some testing, isolating things, It gets better voltage with the lights on if I remove the current output so I put a cap on the current input didn't help, Tried isolation diodes, didn't help, readjusted output voltage by using a 6.2 volt Zener in series with 0.6 Volt forward biased 1n4148. The over charging is better the lights still knock it down 0.5 volts or so I think, needs a little more testing. I think the LT6700-1 Comparator is good to use it's got to be something going on with wiring or something. Maybe the pull up resistance is too low? See the updated schematic below for the updates.

I switched the 6.8 Volt Zener combo to a lower voltage 6.7 volt combo and we took a bit of a trip. Voltages were low 1st half but after driven a couple of hours the regulator started to reach 7.2 volts at the battery at high rpm while only getting the battery up to 6.4 volts with lights. So I am abandoning the 6700i design for now it doesn't hold voltages nearly as well as the 393i design.

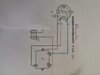

6700i before changes:

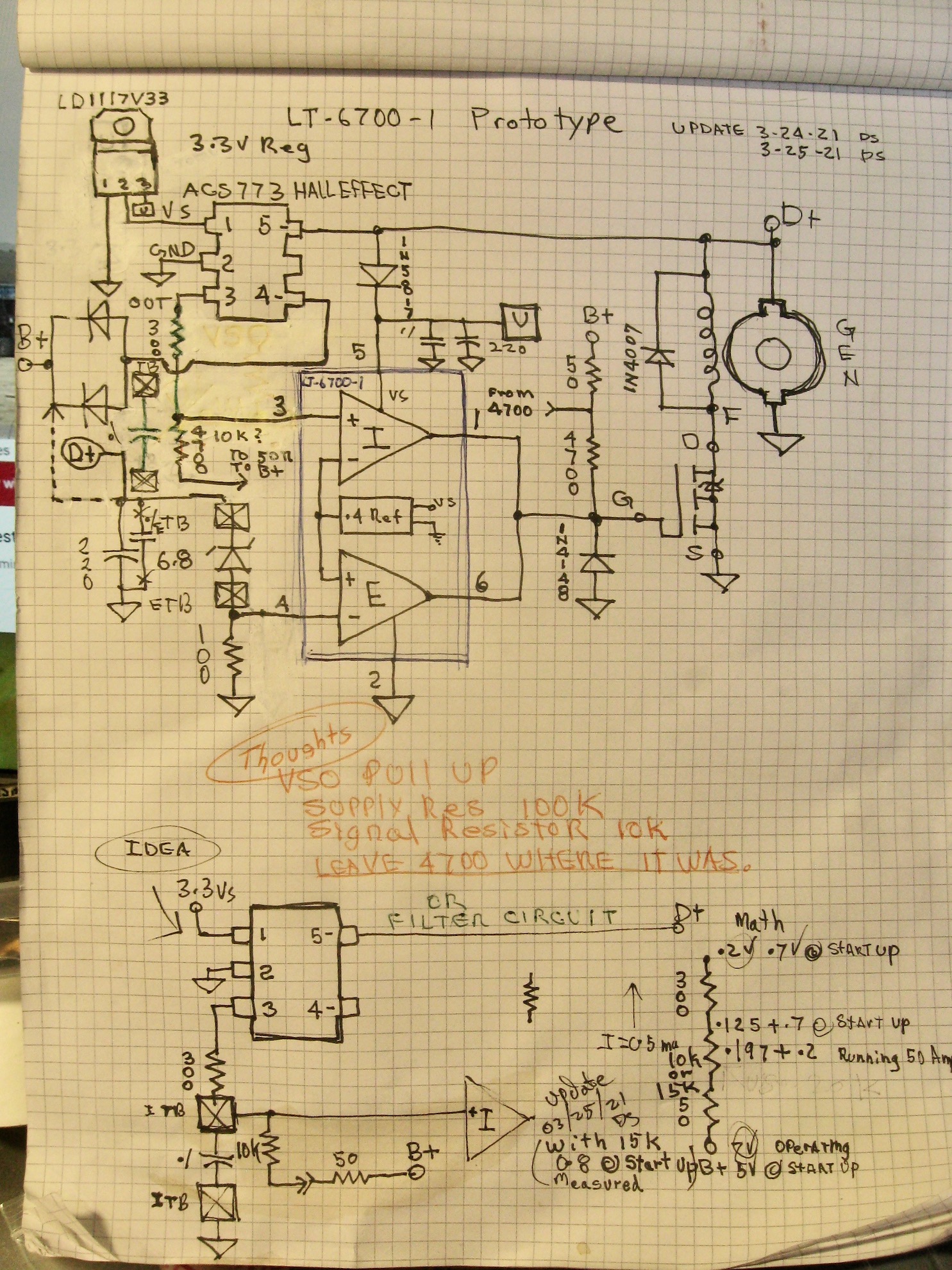

4/23/21 UpDate Schematic 6700i

Scope set at 0.1 volts/div and 1 cm below center, final configuration e input ripple about is about 0.04 Volts PP ready for another test on the car:

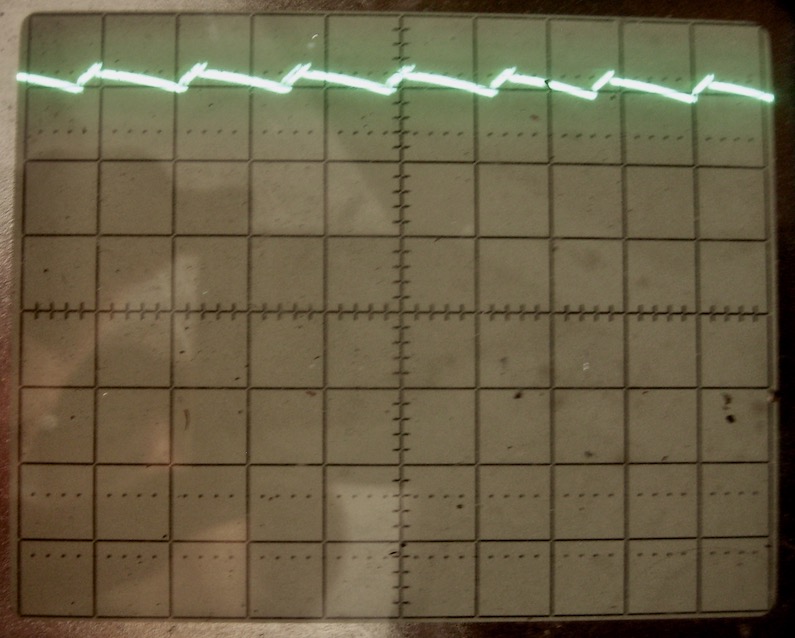

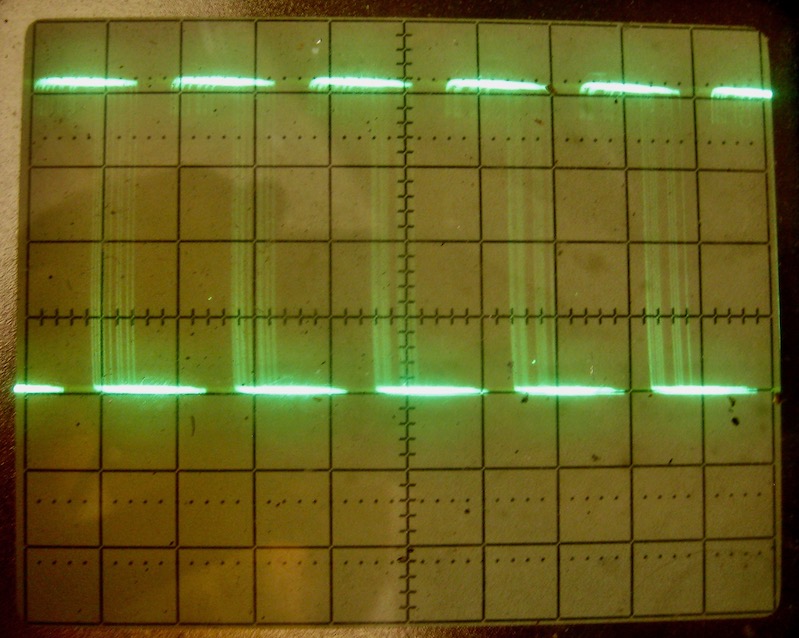

6700i, Scope set at 2 volts/div Field Output signal.

ADCMP350 Data Sheet.

LT-6700-1 Data Sheet.

Some Follow-up on the 6700i prototype, Given the success of the 393i prototype later in this thread and the fact that I can't drive my car right now due to the LF brake locked up, I want to revisit the 6700i prototype. It has what I thought was 2 problems however they could be the same thing. When 1st installed in the car the voltage would surge above regulation voltage which I thought I cured with caps across D+ 2nd with a full battery it over charges the battery unless there is some load on the system like the park lights.

Maybe I will start by trying a voltage limiting filter on D+

One idea that I realized after testing D+ ripple on the scope about 1 volt is to simply feedback the Un-Regulated Supply voltage instead of D+ to the LT-6700-1 Inverting input to control voltage. It would be simpler and it clears up the ripple on the feedback.

Well tried the feedback from the Un-Regulated Supply but it still results and some ripple, Now I am thinking of just incorporating the filer idea into the 6.8 volt Zener used to set the voltage but I did try that on the car with slightly improved regulation however I think it's worth playing with and reducing the value of the series resistor to maybe 16 ohms. Bench testing adding a 820uf filter parallel with a 100 ohm resistor resulted in a rapid flashing LED tail light that I used as a generator output load.

See the Third Schematic below bench test getting 0.28 volts pp ripple at the inv input which is a little improvement, also the D+ output DC regulation when loaded is unchanged something I am pleased with.

April 23, 2021

The 6700i went back on the car today to compare any improvements, Seems a little better, still charges to 7.5 volts at the battery no lights and it is outputting 6.9 Volts at the Regulator with the lights. The 393i was better still. I think what is happening is some noise is triggering the LT-6700 comparator i input, I added a 4.7 uf cap across it to ground it may have helped a little, for now leaving this one on the car for more testing.

Did more testing in the car. definitely too much voltage with the lights off, did some testing, isolating things, It gets better voltage with the lights on if I remove the current output so I put a cap on the current input didn't help, Tried isolation diodes, didn't help, readjusted output voltage by using a 6.2 volt Zener in series with 0.6 Volt forward biased 1n4148. The over charging is better the lights still knock it down 0.5 volts or so I think, needs a little more testing. I think the LT6700-1 Comparator is good to use it's got to be something going on with wiring or something. Maybe the pull up resistance is too low? See the updated schematic below for the updates.

I switched the 6.8 Volt Zener combo to a lower voltage 6.7 volt combo and we took a bit of a trip. Voltages were low 1st half but after driven a couple of hours the regulator started to reach 7.2 volts at the battery at high rpm while only getting the battery up to 6.4 volts with lights. So I am abandoning the 6700i design for now it doesn't hold voltages nearly as well as the 393i design.

6700i before changes:

4/23/21 UpDate Schematic 6700i

Scope set at 0.1 volts/div and 1 cm below center, final configuration e input ripple about is about 0.04 Volts PP ready for another test on the car:

6700i, Scope set at 2 volts/div Field Output signal.

Last edited: