UselessPickles

Active Member

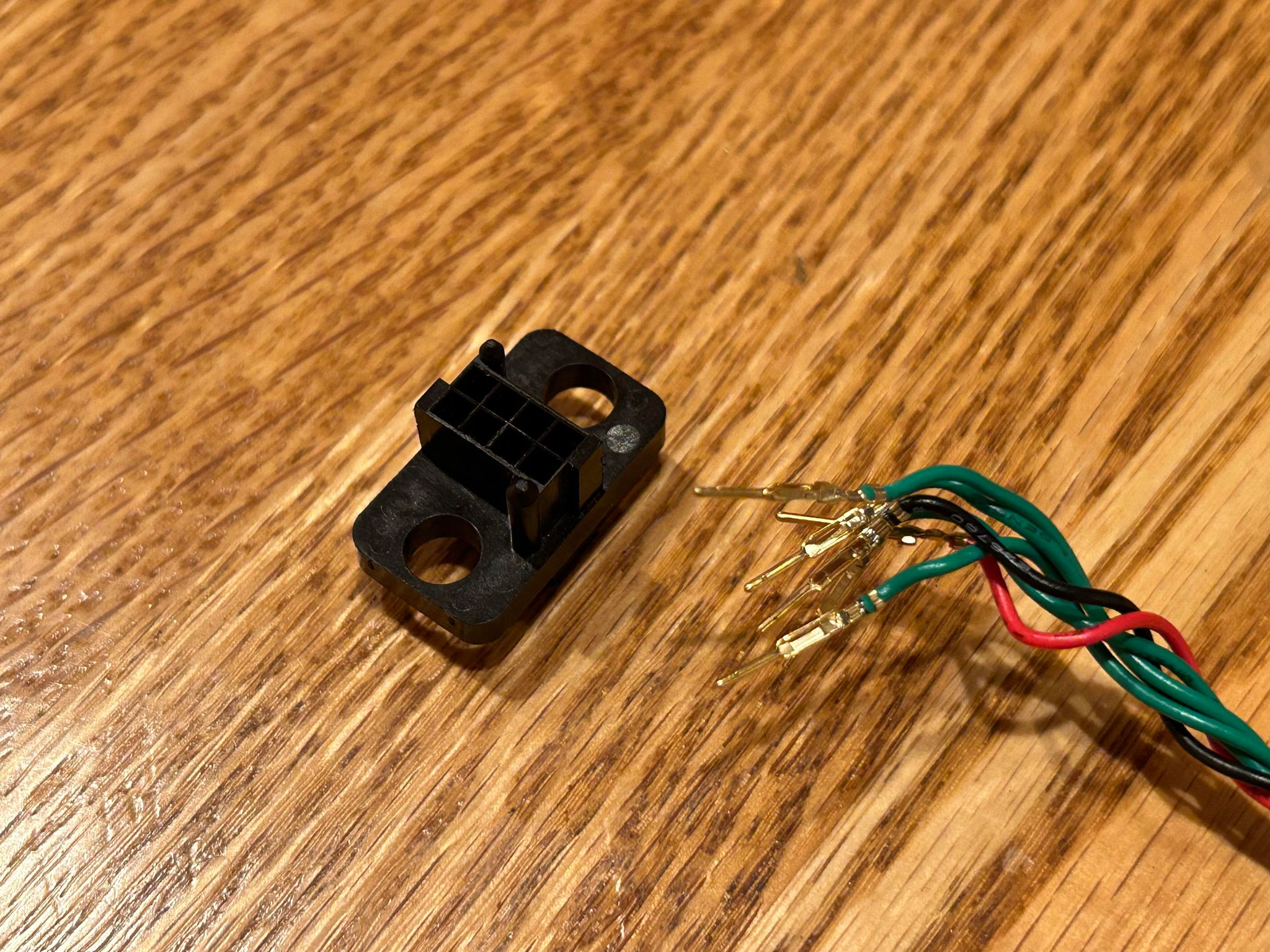

Well, that was easy. Some 22-gauge solid core wire worked great as a de-pinning tool this connector.

I like that this is a simple, non-destructive, and easily/reliably reversible "borrowing" of an original part.

Next I have to see how easily I can de-solder the female pin header from the transceiver circuit board. Good thing I have 7 spare phones, and one of them already doesn't work reliably.

I like that this is a simple, non-destructive, and easily/reliably reversible "borrowing" of an original part.

Next I have to see how easily I can de-solder the female pin header from the transceiver circuit board. Good thing I have 7 spare phones, and one of them already doesn't work reliably.

. I may as well order a few of them.

. I may as well order a few of them.