Hey,

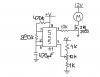

New NOOB here. I want to make a timer circuit, that I can waterproof, to control the on-off cycle of a 12 volt DC, 3 amp or less motor.

It is the aerator pump for the livewell of a fishing boat. I would like to be able to have the pump come on for 30 seconds-2 minutes, then shut off for about 5-15 minutes.

As far as waterproofing, I intend to seal it up in silicone caulking or some such material. Even though it probably won't get wet, it is in a boat and the possibility always exists...

Thanks in advance for any help or suggestions.

BTW, I know a little something, something about electronics, but only as a dummy.

Please, dumb down your explanations, although if you link me to a circuit diagram, I can follow that pretty much OK.

I would also like to keep the whole thing under 2 inches square, if possible.

gus

New NOOB here. I want to make a timer circuit, that I can waterproof, to control the on-off cycle of a 12 volt DC, 3 amp or less motor.

It is the aerator pump for the livewell of a fishing boat. I would like to be able to have the pump come on for 30 seconds-2 minutes, then shut off for about 5-15 minutes.

As far as waterproofing, I intend to seal it up in silicone caulking or some such material. Even though it probably won't get wet, it is in a boat and the possibility always exists...

Thanks in advance for any help or suggestions.

BTW, I know a little something, something about electronics, but only as a dummy.

Please, dumb down your explanations, although if you link me to a circuit diagram, I can follow that pretty much OK.

I would also like to keep the whole thing under 2 inches square, if possible.

gus