Hi SG,

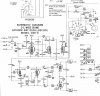

Boy that circuit diagram brings back memories of some scopes I had in the 1960s.

You don not include the time-base capacitors in the schematic, but all scope ramp generators rely on charging/discharging a capacitor with a constant current to generate a linear voltage ramp

From what I can tell V6a acts like a switch which is activated by a trigger input.

When V6a cathode is positive that holds the timing capacitor at a fixed voltage, which would correspond to the dot on the scope CRT screen being at the left.

When the cathode of V6a goes negative, V6b no longer conducts, so no current flows into the timing capacitor from V6b.

But there will be a constant current generator that will remove current from the timing capacitor. If you remove a constant current from a capacitor, you generate a negative going linear ramp voltage across the capacitor.

Just in case you want to know, the rate of change is given by the formula, dV = C/I, where dV is the rate of change of voltage across the capacitor in Volts, C is the capacitance in Farads, and I is the current in amps.

So take a practical example:

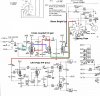

You want the trace to move horizontally at one division per second on the CRT display and each division equates to 1V at the time base generator when you take into account the horizontal amplifier gain (V7 and V8 on your scope).

The minimum constant current your circuit will generate is 100uA say, so the value of timing capacitor would be calculated from C = (I * T)/V = (100uA * 1s)/1V = 100uF.

To change the time-base rate on a scope you just juggle the timing capacitors and the constant current. Typical constant currents would be, 100uA, 200uA, and 500uA.

and these are switched in by the time-base rate selector switch along with the appropriate timing capacitor. These three constants currents would give the often-used 1...2...5 time-base ratios.

When the negative going saw tooth voltage across the timing capacitor reaches a low enough voltage to turn V6a on via its cathode (this corresponds to the dot on the CRT screen being at the right (

correction 2016_12_01) of the screen), V6a will snap on again and restore the dot to the left of the screen awaiting for the next trigger (I think that V5 and V6a are a Schmitt trigger).

It is as simple as that.

spec