MrDEB

Well-Known Member

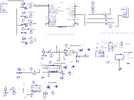

couldn't locate this thread but here is the issue

I breadboarded this circuit and it seems to work driving just an LED but I am driving a 12v led neon strip.

The circuit flashes the strip slowly to fast as per pot adjustment.

The 555 circuit works as planned with one LED (it is supposed to change the duty cycle

Thinking the two different supply voltages has something but what to do? Any suggestions?

NOTE THE 7555 IS POWERED BY THE pic

the MOSFET is logic level

I breadboarded this circuit and it seems to work driving just an LED but I am driving a 12v led neon strip.

The circuit flashes the strip slowly to fast as per pot adjustment.

The 555 circuit works as planned with one LED (it is supposed to change the duty cycle

Thinking the two different supply voltages has something but what to do? Any suggestions?

NOTE THE 7555 IS POWERED BY THE pic

the MOSFET is logic level