Hi guys,

I'm stuck.

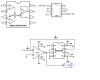

I tried using the following scheme conficurations on a breadboard, but always get a the unique ~ 14V result, without any influence of the two voltage sources:

Attached are the implemntation circuits I used.

- "loads" are the same - preamped photodiodes of the same nature and with a 100KOhm feedback resistor (& parallel 0.1uF capacitor - which give bot when connected to the circuit and when sampled on their own ~ 0.2V-14V, where the 14V is only under direct ilumination, so ambient light ~ 0.2-0.5V). Maybe I need to replace with 1MOhm to producemore than 1V, but I doubt that this is the problem.

I've checked that I'm getting the +15V, -15V and "0" as source to all circuits (my "0" is also my "grd", as I don't see how this can be implemnted otherwise).

I did not opt for the "optional" configs, just a straight wiring with jumpers, necessary resistors and capacitors as suggested.

Any help in understanding why this doesn't seem to work will be greatly appreciated.

-After posting, I switched the RC photodiode feedback to 1MOhm & 1nF (SMD), and got better ambient light response - but still "no cigar"..

I'm stuck.

I tried using the following scheme conficurations on a breadboard, but always get a the unique ~ 14V result, without any influence of the two voltage sources:

Attached are the implemntation circuits I used.

- "loads" are the same - preamped photodiodes of the same nature and with a 100KOhm feedback resistor (& parallel 0.1uF capacitor - which give bot when connected to the circuit and when sampled on their own ~ 0.2V-14V, where the 14V is only under direct ilumination, so ambient light ~ 0.2-0.5V). Maybe I need to replace with 1MOhm to producemore than 1V, but I doubt that this is the problem.

I've checked that I'm getting the +15V, -15V and "0" as source to all circuits (my "0" is also my "grd", as I don't see how this can be implemnted otherwise).

I did not opt for the "optional" configs, just a straight wiring with jumpers, necessary resistors and capacitors as suggested.

Any help in understanding why this doesn't seem to work will be greatly appreciated.

-After posting, I switched the RC photodiode feedback to 1MOhm & 1nF (SMD), and got better ambient light response - but still "no cigar"..

Attachments

Last edited: