I would like to use whole house fans to ventilate my workshop but it would be nice if I they were computer controlled variable speed.

I have done zero crossing, triac thing, once or twice back in the dark ages but never for an inductive load so I am asking for advice.

Suggest circuit/schematic. if not what do I need in the way of a snubber?

Do I want to just use the high speed wire or should the low speed wire be used for lower RPM? Thinking that using the lower speed wire will be more effective at low speeds because the triac can be triggered sooner for a longer on period.

Random info

-----------------

A PIC or ESP8266 will be used for this controller.

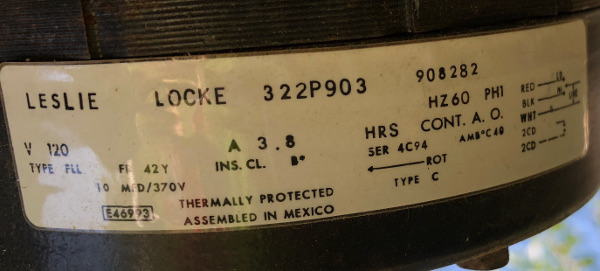

As I understand either 2 separate sets of poles or a transformer is used in motors like this to obtain more than one speed. I have no idea which it is.

3v0

I have done zero crossing, triac thing, once or twice back in the dark ages but never for an inductive load so I am asking for advice.

Suggest circuit/schematic. if not what do I need in the way of a snubber?

Do I want to just use the high speed wire or should the low speed wire be used for lower RPM? Thinking that using the lower speed wire will be more effective at low speeds because the triac can be triggered sooner for a longer on period.

Random info

-----------------

A PIC or ESP8266 will be used for this controller.

As I understand either 2 separate sets of poles or a transformer is used in motors like this to obtain more than one speed. I have no idea which it is.

3v0