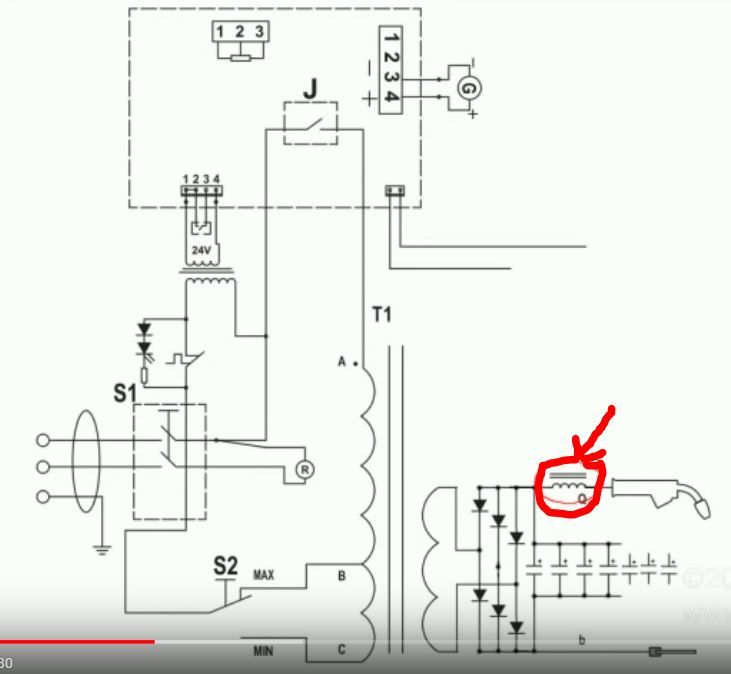

The core of a transformers and inductor can come in many different shapes. A toroid is just one of the many shapes, just like a cylinder is, or a square, or an shape that looks like an "El"

If that is a choke, and I'm not saying it is, then it is a differential choke (as opposed to a common-mode choke). A choke is basically an inductor optimized to be lossy at high frequencies (by virtue of selection of the core material) so it bleeds off the high frequency energy. It's an inductor made specifically to be inefficient at high frequencies so they are dissipated as heat.

Just to fill in the gaps, a differential choke is something similar but is a transformer instead and is current of two lines is passed each winding such that the magnetic fields cancel out inside the transformer so high frequencies that are common to both lines are suppressed.

A toroidal transformer (or any transformer really) can be rewound with just a single loop of wire to turn it into an inductor. or you can leave the toroidal transformer wound and connect the primary and secondary windings in series with each other in the appropriate direction so it becomes an inductor. Technically, you could also use a transformer with all but one winding open and then it would become an inductor as well. Of course if you do this it's an efficient use of wire and you have a bunch of open connections which could be at very high voltages. Whether or not it will act as a choke (to bleed off high frequency energy as I described above) is dependent on the core material used.

The sections bolded sections above might directly answer at least some of the question you asked.

Now, I don't know anything about welding, but I think that inductor so that the charge stored in the capacitor does not instantly discharge and short-circuit across the workpiece causing a short but brilliant flash. If I'm right, it's to regulate the current coming out of the capacitors in the crudest way. So in that sense, it's not really a choke in the sense that it's supposed to dissipate high frequency energy.

What size bleed resistor? Normally I would say at at least 1 megaohm. Possibly higher depending on how high a voltage your thing runs at and how low current it runs at. The higher the voltage or the lower the current, the higher the resistor you should use.

HOWEVER, these types of values only ensure that the capacitors won't stay charged at lethal levels for a day or more after you've turned the thing off. They don't make the caps rapidly safe as much as they ensure that if someone touches it a day or a week later they get shocked to death. It can take minutes or more for the caps to discharge to safe levels with these values of bleed resistors.

With a welder where the cap terminals are clearly exposed to the outside and can be easily touched, it might be standard to go with much lower value bleed resistors so they discharge very rapidly after the machine is turned off to make it safe.

In this thread a similar question was asked:

https://www.electro-tech-online.com/threads/questions-re-mig-welder-circuit.88194/

That resistor is 50ohm and there is discussion about why it is so low and beefy with regards to power handling. 50ohms would indeed discharge the caps extremely quickly so that the welding tips would not be hazardous shortly after the welder was turned off. The thread also has some theorizing that the resistor does double duty in that it allows a "relief" current path to across the capacitors when the current is interuppted since the inductor would cause a very high voltage kick if the current had no where to flow, damaging components.

Inductors store energy in their magnetic field and use it to smooth out changes in current. If you interrupt current flowing through an inductor, it will release that stored energy to try and keep that current going at similar levels (by producing a voltage, sometimes a very high voltage, that will push that current to smash through anything in the way in an effort to maintain it's present level).