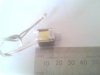

Hello, I was wondering if anybody could help me design a valve that is about a 1/2 inch by 1/2 inch. I need it to be controlled by a tiny electromagnet, or something that can be controlled by electricity.

I have one design, however I am having trouble with leakage, that is why i'm looking for a better design.

I have one design, however I am having trouble with leakage, that is why i'm looking for a better design.