ADWSystems

Member

Not quite working yet...

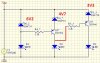

The circuit in my head was along these lines. It's a take off of the zener based bar graph display.

But I haven't gotten it working in the simulator yet. I know I missing something.

After it does work, it won't be finished because the brightness of the lamps (indicated by LEDs in the drawing) will vary with the input/signal voltage.

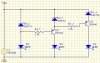

The circuit in my head was along these lines. It's a take off of the zener based bar graph display.

But I haven't gotten it working in the simulator yet. I know I missing something.

After it does work, it won't be finished because the brightness of the lamps (indicated by LEDs in the drawing) will vary with the input/signal voltage.