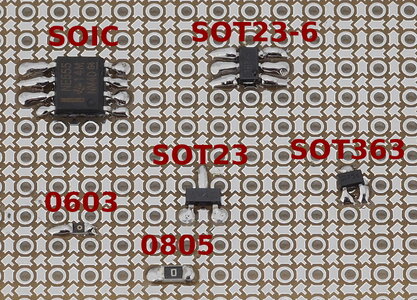

I was looking into different methods for making prototypes with surface-mount components and I stumbled upon this prototyping board design (see attached image). Here's a link to the github page of the person who designed the board in the attached image: https://github.com/electroniceel/protoboard.

I was wondering whether anyone here has any experience with these boards or something similar. I usually do point-to-point prototypes or solder components to a ground plane (copper clad board) but neither of these techniques work very well with surface mount components although I imagine it would not be impossible to use a copper clad board for larger SMT packages (1206, SOT-23, etc.).

I was wondering whether anyone here has any experience with these boards or something similar. I usually do point-to-point prototypes or solder components to a ground plane (copper clad board) but neither of these techniques work very well with surface mount components although I imagine it would not be impossible to use a copper clad board for larger SMT packages (1206, SOT-23, etc.).