Mexon

New Member

Hi

I'm in the process of hooking up my digital camera to a slide projector so that I can digitise my slide collection, using the 'Clickslide' method detailed at https://www.slsprr.net/clickslide/default.html. The Clickslide control box is working well, but my slide projector is too primitive. It has no control circuit to stop each slide in the right place. The length of time required to change slides continually varies, so most slides are not being delivered to the right place in front of the camera. I therefore need some kind of limit switch circuit to reliably stop the slide delivery arm.

I think that I have devised a way of doing this, described below, but I haven't designed any kind of circuit since I was at school. Consequently I've forgotten most of what I knew about electronics, and would really appreciate some help to review the design and resolve a few queries.

Concept

My plan is to use a micro switch (Switch2 on the diagram below) to stop the 'slide delivery arm' at the right place. However after this has broken the circuit, I need some way of reenergising the circuit after a couple of seconds to swap slides (the micro switch being still held open by the 'slide delivery arm').

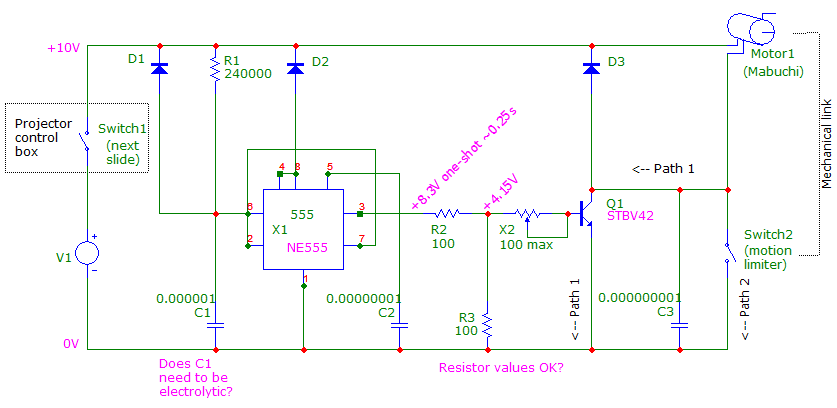

To get around this, my idea is that when the "next slide" switch is closed (Switch1), a 555 circuit will deliver a single pulse for around 0.25 seconds. If I feed this into the base of a transistor it will open up 'Path 1', allowing the motor to run for around 0.25 seconds, bypassing the open limit switch (Switch2). This 0.25 seconds allows more than enough time for the 'slide delivery arm' to have moved, releasing Switch2 and opening up 'Path 2', so allowing the 'slide delivery arm' to keep moving until it returns with the next slide and opens Swich2 again, so stopping in the right place.

Components

1) Motor. The 'slide delivery arm' is operated by a 1970s vintage Mabuchi motor. I don't have any way of measuring the current it takes, but have tracked down a motor of similar physical size and voltage on Mabuchi's web site, which draws 0.26A when operating at optimum efficiency, and 0.84A when stalled. So I guess that the existing motor is similar.

2) 555. I'm proposing to use an NE555. I understand that most non-CMOS 555s can source around 200mA, which seems adequate.

3) Transistor. I'm proposing to use an STBV42 that I tracked down on ebay. The datasheet (https://www.st.com/web/en/resource/technical/document/datasheet/CD00002128.pdf) says that it can cope with a maximum 1A load, which seems OK if my assumption about the motor is reasonable. It can also withstand a base current of 0.5A and, since I understand that 555s can only source around 200mA, that sounds comfortably safe. I'm less clear on the value of hFE to use - there are several values listed ranging from 5 to 30. But if I assume a current through the motor of 0.75A and hFE of 10, then I need a base current of 75mA - less than half of what the 555 can deliver, which also sounds safe.

Uncertainties

Apart from major questions like 'will it work', I have a few specific questions and uncertainties:

a) 555. Unless I've slipped up, thanks to Andy Clarkson's 555 circuit design software (https://clarkson-uk.com/555-timer/), I'm confident that the 555 will work. I guess that there is no reason why I can't upgrade C1 from electrolytic to metalized polyester?

b) R2 & R3. I'm less confident on the resistor values I've chosen for this voltage divider. Is 100 Ohms reasonable?

c) X2. My thinking here is that, based on the above hFE calculation, I may need a bias current of around 75mA - but in case that's not enough, to aim for 100mA. So if the base-emitter voltage is around 3.45V (4.15 - 0.7V), the bias resistor would need to be around 34.5 Ohms - and choosing a 100 Ohm trimmer might not be a bad idea so I can adjust it?

d) Not part of the sketch below, but the existing 10V DC supply within the projector is supplied from a transformer via what appears to be a 1970s vintage bridge rectifier package, without any smoothing. I guess that it might be a good idea to put a capacitor across the output? Something like a 25V 1000uF?

e) What have I missed?

Your feedback, comments and suggestions would be very welcome. I'm away for the weekend, so won't be able to respond to any replies or queries until Monday. Circuit diagram attached:

I'm in the process of hooking up my digital camera to a slide projector so that I can digitise my slide collection, using the 'Clickslide' method detailed at https://www.slsprr.net/clickslide/default.html. The Clickslide control box is working well, but my slide projector is too primitive. It has no control circuit to stop each slide in the right place. The length of time required to change slides continually varies, so most slides are not being delivered to the right place in front of the camera. I therefore need some kind of limit switch circuit to reliably stop the slide delivery arm.

I think that I have devised a way of doing this, described below, but I haven't designed any kind of circuit since I was at school. Consequently I've forgotten most of what I knew about electronics, and would really appreciate some help to review the design and resolve a few queries.

Concept

My plan is to use a micro switch (Switch2 on the diagram below) to stop the 'slide delivery arm' at the right place. However after this has broken the circuit, I need some way of reenergising the circuit after a couple of seconds to swap slides (the micro switch being still held open by the 'slide delivery arm').

To get around this, my idea is that when the "next slide" switch is closed (Switch1), a 555 circuit will deliver a single pulse for around 0.25 seconds. If I feed this into the base of a transistor it will open up 'Path 1', allowing the motor to run for around 0.25 seconds, bypassing the open limit switch (Switch2). This 0.25 seconds allows more than enough time for the 'slide delivery arm' to have moved, releasing Switch2 and opening up 'Path 2', so allowing the 'slide delivery arm' to keep moving until it returns with the next slide and opens Swich2 again, so stopping in the right place.

Components

1) Motor. The 'slide delivery arm' is operated by a 1970s vintage Mabuchi motor. I don't have any way of measuring the current it takes, but have tracked down a motor of similar physical size and voltage on Mabuchi's web site, which draws 0.26A when operating at optimum efficiency, and 0.84A when stalled. So I guess that the existing motor is similar.

2) 555. I'm proposing to use an NE555. I understand that most non-CMOS 555s can source around 200mA, which seems adequate.

3) Transistor. I'm proposing to use an STBV42 that I tracked down on ebay. The datasheet (https://www.st.com/web/en/resource/technical/document/datasheet/CD00002128.pdf) says that it can cope with a maximum 1A load, which seems OK if my assumption about the motor is reasonable. It can also withstand a base current of 0.5A and, since I understand that 555s can only source around 200mA, that sounds comfortably safe. I'm less clear on the value of hFE to use - there are several values listed ranging from 5 to 30. But if I assume a current through the motor of 0.75A and hFE of 10, then I need a base current of 75mA - less than half of what the 555 can deliver, which also sounds safe.

Uncertainties

Apart from major questions like 'will it work', I have a few specific questions and uncertainties:

a) 555. Unless I've slipped up, thanks to Andy Clarkson's 555 circuit design software (https://clarkson-uk.com/555-timer/), I'm confident that the 555 will work. I guess that there is no reason why I can't upgrade C1 from electrolytic to metalized polyester?

b) R2 & R3. I'm less confident on the resistor values I've chosen for this voltage divider. Is 100 Ohms reasonable?

c) X2. My thinking here is that, based on the above hFE calculation, I may need a bias current of around 75mA - but in case that's not enough, to aim for 100mA. So if the base-emitter voltage is around 3.45V (4.15 - 0.7V), the bias resistor would need to be around 34.5 Ohms - and choosing a 100 Ohm trimmer might not be a bad idea so I can adjust it?

d) Not part of the sketch below, but the existing 10V DC supply within the projector is supplied from a transformer via what appears to be a 1970s vintage bridge rectifier package, without any smoothing. I guess that it might be a good idea to put a capacitor across the output? Something like a 25V 1000uF?

e) What have I missed?

Your feedback, comments and suggestions would be very welcome. I'm away for the weekend, so won't be able to respond to any replies or queries until Monday. Circuit diagram attached: