Mr RB

Well-Known Member

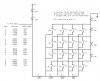

Easy as pie. Just put the E and RS on their own 2 pins, then connect 2 PIC pins to D4 and D5, and connect the same 2 PIC pins to D6 and D7 with 2 RC networks.

Same basic system as my Shift1-LCD uses, but a derivative. You hold the 2 D pins steady until the 2 caps charge to the required level (the cap voltages will control D6 and D7), then set the 2 D pins to the values you want for D4 and D5, then strobe E within a few uS before the caps have time to change voltage again.

This should give quite high data rates and only needs 4 PIC pins to derive the 6 needed for operating the LCD. Total cost 2R and 2C.

Same basic system as my Shift1-LCD uses, but a derivative. You hold the 2 D pins steady until the 2 caps charge to the required level (the cap voltages will control D6 and D7), then set the 2 D pins to the values you want for D4 and D5, then strobe E within a few uS before the caps have time to change voltage again.

This should give quite high data rates and only needs 4 PIC pins to derive the 6 needed for operating the LCD. Total cost 2R and 2C.