bitem2k

New Member

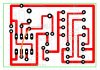

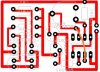

Im trying to design a PCB to make a simple 4-led strobe light, with a 555 timer chip. I have made the circuit on a breadboard several times, and have simulated it in croc-clips, however when i make the pcb, flip the design and etch it it just doesnt seem to work. All the pins of the 555 are correctly in their positions when i solder them.

The only thing that happens when i turn the circuit on is all the leds simply turn on. (this is mildly better than before, when i didnt flip the image, the 555 timer just got really hot!)

could someone please take alook at the attached pics and tell me whats wrong with the PCB i have designed. Its driving me mad, as I cant work out why the circuit does not work.

i would be extremely grateful if someone could work this one out .

.

thanks.

The only thing that happens when i turn the circuit on is all the leds simply turn on. (this is mildly better than before, when i didnt flip the image, the 555 timer just got really hot!)

could someone please take alook at the attached pics and tell me whats wrong with the PCB i have designed. Its driving me mad, as I cant work out why the circuit does not work.

i would be extremely grateful if someone could work this one out

thanks.