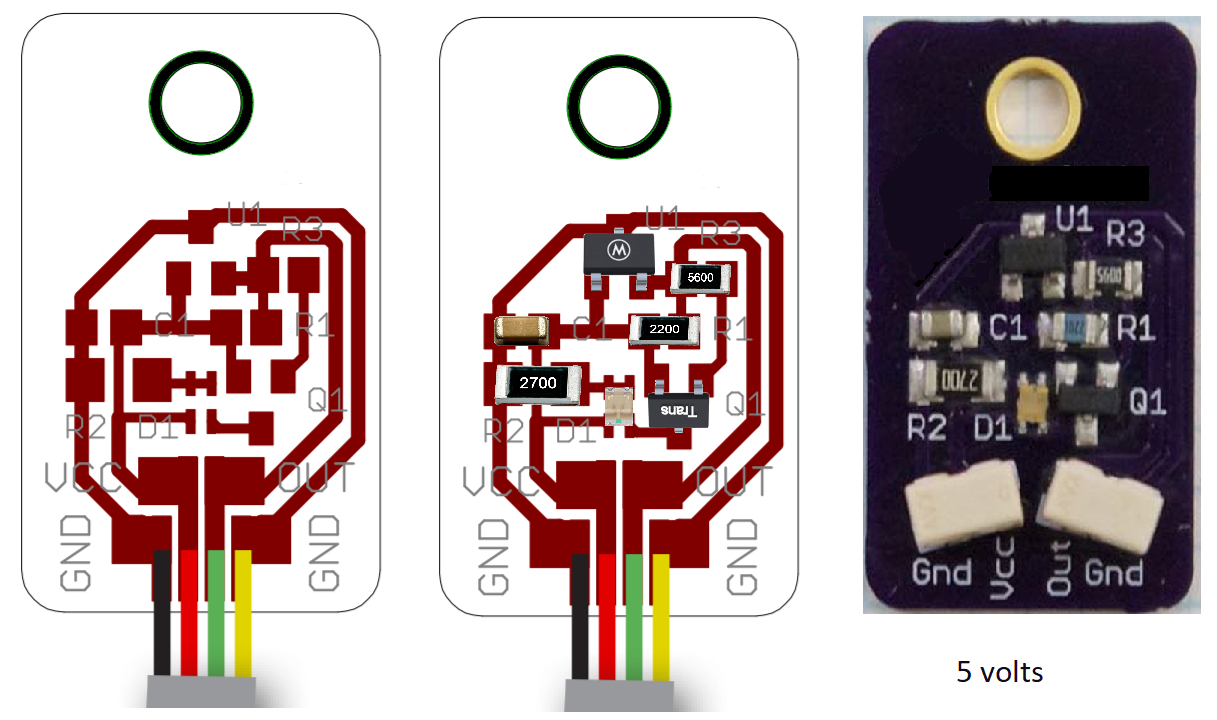

I have a broken sensor and the original manufacturer has stopped producing. I have no electronics experience, and I'm trying to reverse engineer this thing can somebody help calculate the resistor and capacitor sizes.

i picked these for the bi color led and hall affect sensor

i appreciate any help

Madaxe

i picked these for the bi color led and hall affect sensor

i appreciate any help

Madaxe

| uk.rs-online.com | min (Volt) | max (Volt) | forward voltage (Volt) | length (mm) | width (mm) | height (mm) |

| A1126LLHLT-T Allegro Microsystems, Omnipolar Hall Effect Sensor, 3-Pin SOT-23 | 3 | 24 | 3 | 2 | 1 | |

| 2.5 V Green & Red LED 2012 (0805) SMD, Kingbright KPHBM-2012SURKCGKC | 2.4 | 2 | 1.5 | 0.5 |