350mA -750mA for the lcd back lights of many the normal cheapo Chinese ones. The segment display LCD's can run as low as <10uA even when on, check out the ones on the say the sil labs Gecko boards. I have a gecko board that tell the time,takes temperature and humidity reading every 5 mins and displays it all the time, so far my single cell watch battery has powered it for just over 2 years.

Your 3AA batteries are likely to last no more than maybe a day tops.

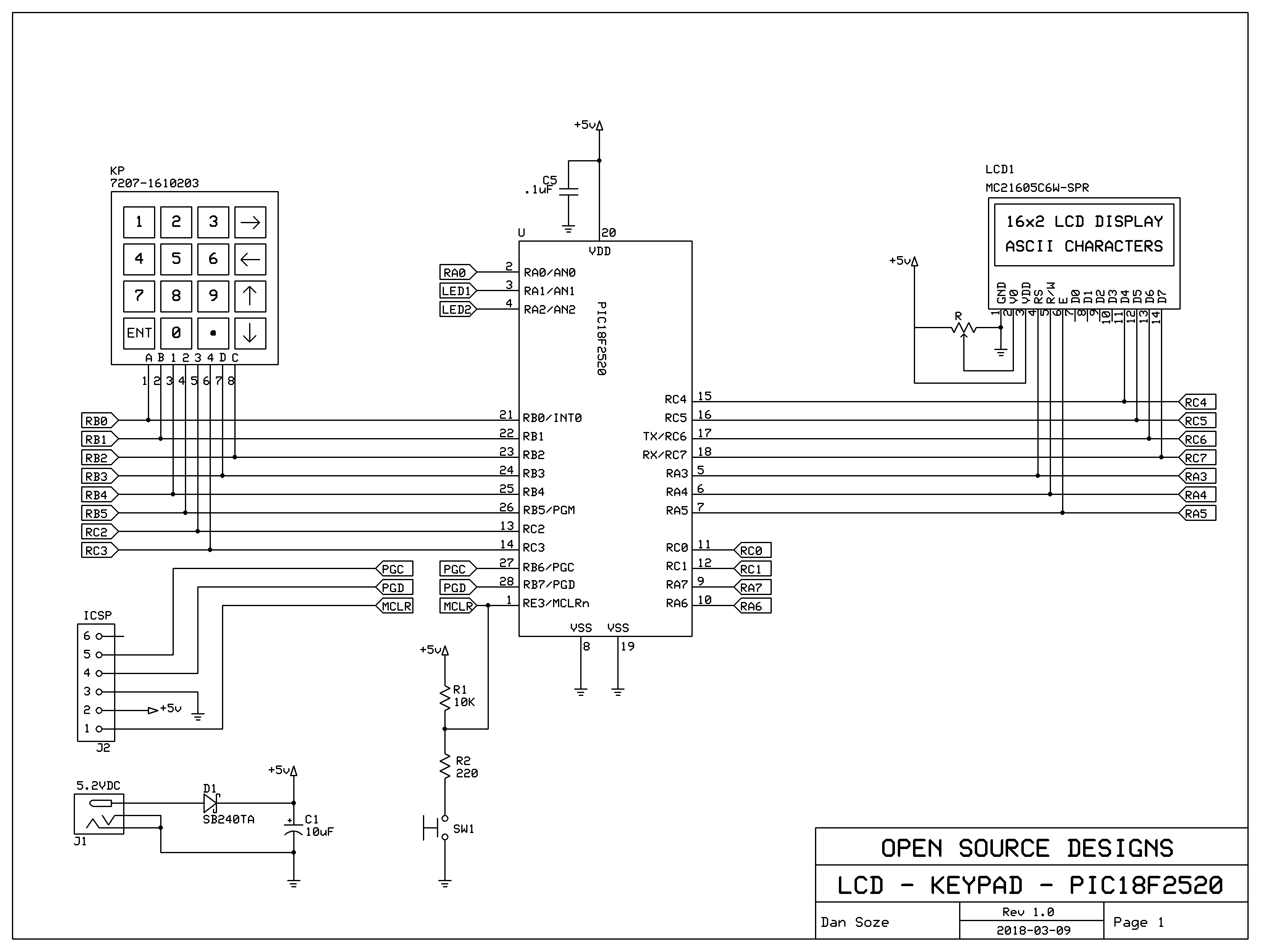

If you dont want a LDR on the display then use a pot to drop the light output, you rarely need a lcd full wack unless the sun is bright, assuming your using a hitachi type lcd then put a pot or trimmer on pin 3 (rusty memory but i am pretty sure its pin 3 for contrast) and adjust the LCD contrast and back light to get a hal decent display. I have both types of LCD with and without backlight, in most situations i have never needed the back light.

Most of mine pull around 350mA but a few pull 750mA, with a pot on or..........pwm (please pick pot) you can drop this right down, i think most situations with a backlight you can get away with 10-20% pwm so turn the backlight right down.

One the most common mistakes is constant updating of the display, the program on each loop outputs the display regardless if its changed or not!! What is the point of writing the same thing to the display each loop? No idea if your code does this i havnt looked, i wont look as i promised myself i wouldnt look.

Seriously though your micro in sleep will save nothing compared to dropping leds, turn off the back light until needed. Why use a switch? Just have the micro turn the light on or off via a transistor or LLMosfet.

Its 2018, how tacky and stone age to reach over for a switch just to see the screen? If it is only used mainly at the end then when the micro does the final output get it turn on the back light, wiggle it with pwm and have a low duty cycle, its only about 4 years of code to that.

You could get the Lcd to flash an asterix on and off every few seconds as a kind of heart beat. Two leds not directly in the game are 40mA of pure waste, sleeping the micro wont get you that back. On the gecko board it sleeps, but with that it wakes every five mins and takes the readings, it displays them and the display stays on when the micro is asleep. You dont have the right chip for those displays however as they need a driver on the chip and alot of pins.

But you can get close to it, do a software step map of the game. They save you loads of effort, work out what you need on and when. BTW cap touch switches use very little current.... What you like on cap touch Johnsea? lol