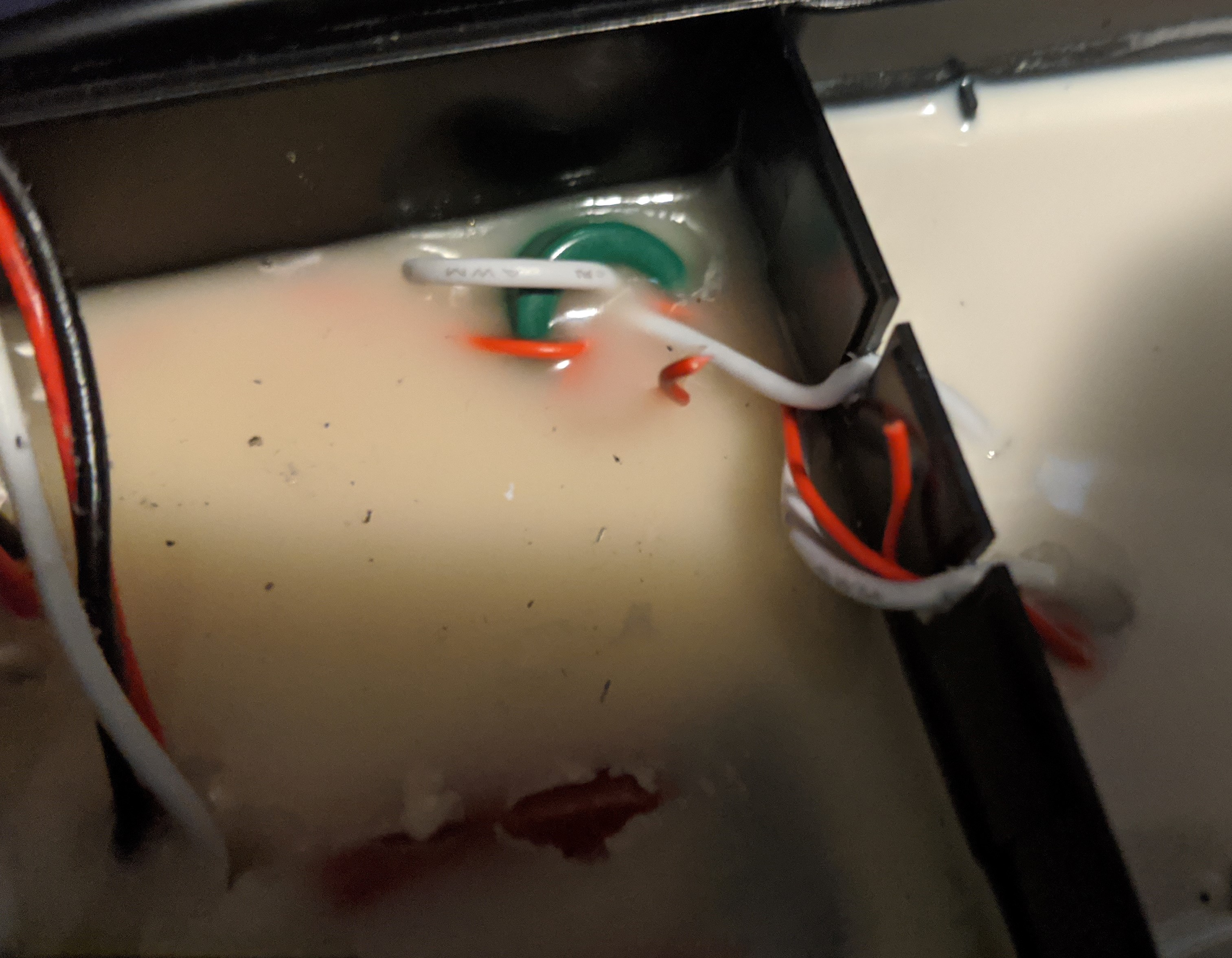

Build an RQ variable speed vacuum fan spark gap = RQVSVFSG. Put 9 copper pipes 3/4" x 2" long inside a 4" pvc pipe 6" long. Gap between each copper pipe is .030". Drill clearance holes in copper pipe 1" apart for 3/4" long 6-32 screws. Drill 1/4" holes in pvc pipe for the screws the over size holes allows you to adjust spark gap to .030" very easy. Buy a $3 vacuum cleaner from yard sale or goodwill store remove electric not with fan. Mount vacuum motor on 1 end of 4" pvc pipe. Put 4" pvc pipe in a pvc toilet flange to block air flow through pvc pipe and toilet flange acts like legs to hold spark up right. No air can flow through pipe so you need to drill 3/16" diameter holes in rows 2" long in the side of the pvc pipe so air is sucked in threw the holes at high speed to break all 8 spark gaps. My Harddrive crashed years ago I lots all my good pictures. You also need a variac to adjust the speed of the vacuum fan.

As you turn the variac dial vacuum motor turns faster and faster. As air is sucked into over the sparks gaps the gaps all break at higher and higher frequency. As vacuum motor picks up speed out put arcs and sparks of your tesla coil get longer and longer. What you have is a variable frequency spark gap controlled by the variac. I have used this on my 14KV 30ma TC and also my 14KW TC.

The guy that mastered rotory 20 years ago said, WHY would anyone want a rotor when you can have a RQVSVFSG. For some reason this never caught on everyone had rotor on the brain. A few people on the old TC forum built a RQVSVFSG and said the same thing, why would anyone want a rotor when you can have a RQVSVFSG. It still never caught on and I gave up telling people about it.

RQVSVFSG is so simple turn the variac dial it takes 5 seconds to adjust to maximum tesla coil output. Make changes to your TC turn the dial you get max output in a few seconds just turn the variace dial. Move the RQVSVFSG to other Tesla coils it takes 5 seconds to dial in maximum output.

You can see my RQVSVFSG in the first picture setting on the table next to the left TC. I had alligator clips on the RQVSVFSG I could move it to a different TC in a few seconds. I use to have 7 TCs all sizes from 6K 30ma to 14KW. I build all my caps to be rated 40,000. I wanted everything to be bullet proof and work perfect.

My big TC is 10" diameter it runs best at 12KW and produces 12 foot long arcs from the 3 ft diameter sphere. I can make a 27 ft diameter circle or spark & arcs in the back yard.

Flat wound primary with strike rail works best.

950 turns on the secondary works best.

Secondary diameter to length ratio 5 to 1 is best.

I tried, tested, experimented with everything.

I still have 2 rolls of #24 enamel coated copper wire each roll weight is about 80 lbs. Sold all my coils, spark gags, caps, other wire. It was FUN for many years.

I built double layer and triple layer secondary coils. Wind 1 coil 950 turns test it for max output then wind another 950 turn secondary over the first secondary connect the 2 secondary coils in parallel test it out put is about 5% better than before. 3 secondary coils over top each other gets better too not much about 7% better than 1 secondary.

HV = 14KV