The CAM processor for my NPTH layer has only the dimension layer and hole layer included, without the drills layer. It pops up a message every time asking if it's ok that holes are selected but drills are not but only non-plated holes show up in the output. The top and bottom copper layers have neither drills nor holes included. Give this a try and see what happens.

I just cannot find a way to do this. I do not see any options that allows a gerber file to be generated with circles for the holes.

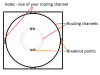

I can generate the drill drawing (third tab) that has differently shaped same size symbols for the drill locations (uses .Legend to show the drill sizes). I can also generate a drill guide (fourth tab) that has varying + symbols for each hole (does not indicate the specific hole size just where and may be different size).

I have 14 mechanical layers, 16 internal planes, and 30 mid layers I can add, but nothing that is specific for showing only the NPTH holes. If I (have to) do this it looks like it will have to be done manually. (unless someone recalls how to do this in Protel 99SE)

However, I did find a way to include the board outline on each layer without having to draw it on each layer (a setting on the Mech Layers tab #5).

Now the mounting pads are too close to the keep out line which on top and bottom will turn into copper.

Looks like I have some squishing to do.

Update: Moving the board outline so it shows up on all layers had a negative side effect. Although it prints on the keep out layer, it isn't on the keep out layer so no design rules to the board edge are enforced.

Looks like I have to have the board outline on two layers, a mechanical layer and the keep out layer, if I want the auto router to stay in bounds and the board outline to show in all gerber files.