Deepak Kamble

New Member

Hi every one,

I desperately need your help.

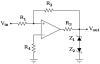

I would like to amplify and regulate an input signal. The input voltage is variable i.e 50mv to 30volt ac, The frequency is 0-20000/min which is varying continously. . The pulse will go to the input of a micro-controller. But the problem is the micro-controller need 5 volt to sense the trigger. The applications are many, but due to the input pulse voltage I couldn't proceed further. I Thought of adding an op-amp as an amplifier or a comparator in between the pulse coil and the micro-controller but Its out of the box for me. Will someone help me. Few of my friends suggested me to use op-amp as a comparator or voltage amplifier.

I desperately need your help.

<Mod edit> Repeatedly saying "Plz" will not get you answers any faster, and will only annoy the other members here. Thus, I have removed them from your post.

I desperately need your help.

I would like to amplify and regulate an input signal. The input voltage is variable i.e 50mv to 30volt ac, The frequency is 0-20000/min which is varying continously. . The pulse will go to the input of a micro-controller. But the problem is the micro-controller need 5 volt to sense the trigger. The applications are many, but due to the input pulse voltage I couldn't proceed further. I Thought of adding an op-amp as an amplifier or a comparator in between the pulse coil and the micro-controller but Its out of the box for me. Will someone help me. Few of my friends suggested me to use op-amp as a comparator or voltage amplifier.

I desperately need your help.

<Mod edit> Repeatedly saying "Plz" will not get you answers any faster, and will only annoy the other members here. Thus, I have removed them from your post.

Last edited by a moderator: