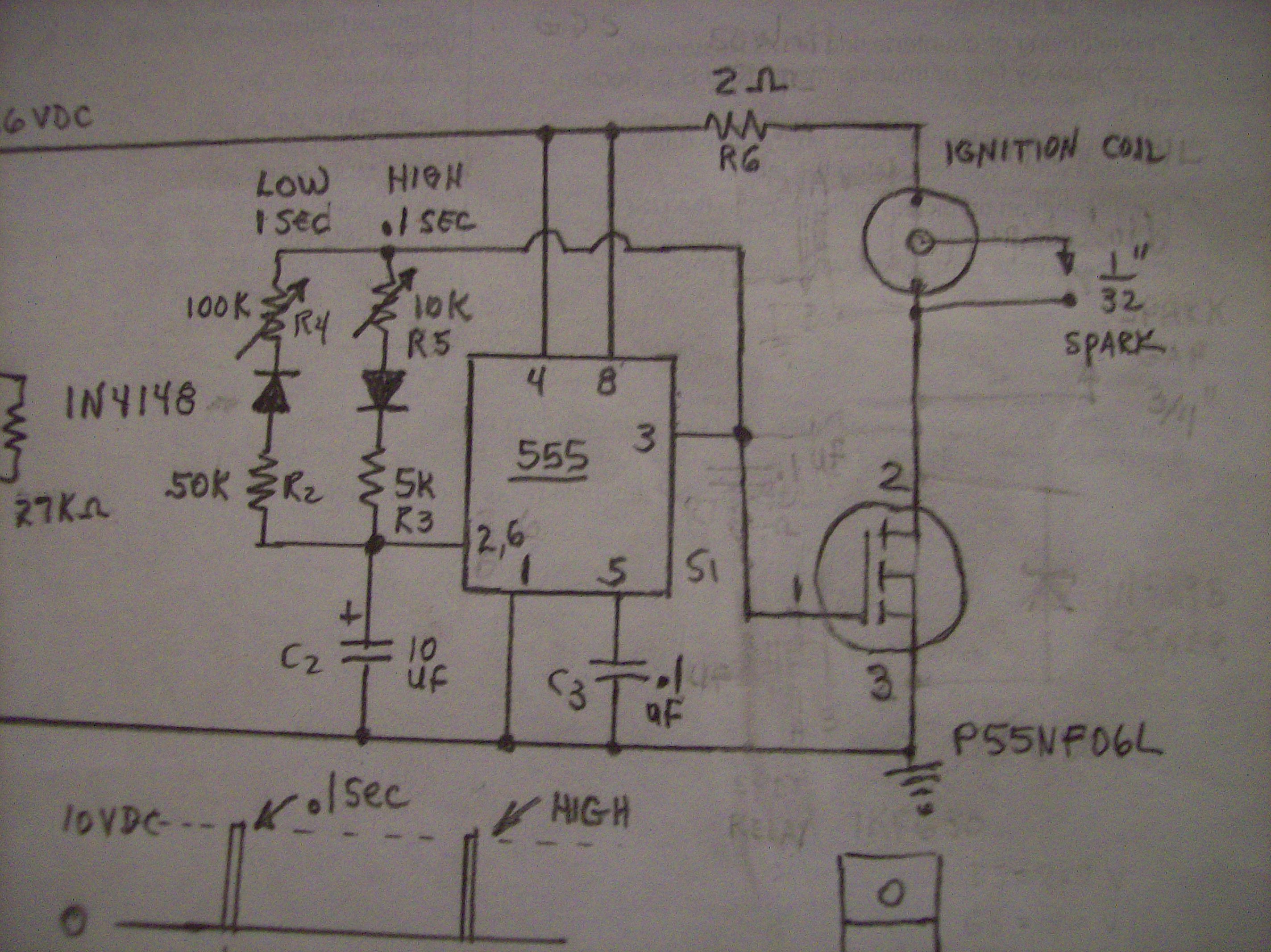

After thinking about this circuit for a while I decided PS should not have unlimited amps maybe that is why mosfets will not turn off. I also took a lesson I learn from induction heaters use the heat sink tap for mosfet output and cut pin 2 off. I tested all the mosfets I already used they all test good. I put a 1 ohm resistor on B+ and the circuit works the light bulb flashes on/off. I connected the ignition coil and it makes a 1/16" spark. Next I tried a 2 ohm resistor now coil makes a 1/32" spark. I tried a 3 ohm resistor the coil makes high voltage but not enough to make a spark. The little 2 watt resistor get hot enough to cook an egg in 10 seconds it had to be changed to 50 watt 2 ohms. I changed the 555 timer adjustment so it is OFF for 2 seconds then flashes ON for .1 seconds the LED is flashing the correct speed but the ignition coil seems to be pulling too many amps. How can it be pulling so many amps to need a 50W resistor when the circuit is off 99% of the time?