Hi all,

I am trying to design and test a type II compensator for a synchronous boost converter. I obtained the control-to-output transfer function (credits to "Fundamentals of Power Electronics by R W Erickson") for the ideal case. The circuit parameters are:

Vin = 42V

Vout = 189V (approx 77% duty)

L = 1mH

C = 1000uF

Load = 4170VA

The PWM controller is the UC3823n with Vm = 1.8V (peak to peak).

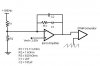

In order to eliminate the effect of the Right Hand plane zero and in order to move the cross-over frequency further, I designed a type 2 compensator (please see attached diagram) for a 5% overshoot and a < 0.1s settling time (on MATLAB).

The thing is IT DOESN'T WORK. Either the output is 44V or just erratic.

As I am not yet at under any serious load condition (large output impedance), could this be the cause of the poor operation of the control system? I replaced the UC3823n with a simple function generator and the boost gave 192Vdc with 77% duty (means my power-electronics setup is ok).

Can anyone suggest values for R3,C1,C2 for the compensator (as per the attached diagram)?

Regards

ed

I am trying to design and test a type II compensator for a synchronous boost converter. I obtained the control-to-output transfer function (credits to "Fundamentals of Power Electronics by R W Erickson") for the ideal case. The circuit parameters are:

Vin = 42V

Vout = 189V (approx 77% duty)

L = 1mH

C = 1000uF

Load = 4170VA

The PWM controller is the UC3823n with Vm = 1.8V (peak to peak).

In order to eliminate the effect of the Right Hand plane zero and in order to move the cross-over frequency further, I designed a type 2 compensator (please see attached diagram) for a 5% overshoot and a < 0.1s settling time (on MATLAB).

The thing is IT DOESN'T WORK. Either the output is 44V or just erratic.

As I am not yet at under any serious load condition (large output impedance), could this be the cause of the poor operation of the control system? I replaced the UC3823n with a simple function generator and the boost gave 192Vdc with 77% duty (means my power-electronics setup is ok).

Can anyone suggest values for R3,C1,C2 for the compensator (as per the attached diagram)?

Regards

ed