Hi, 1st post so be gentle!

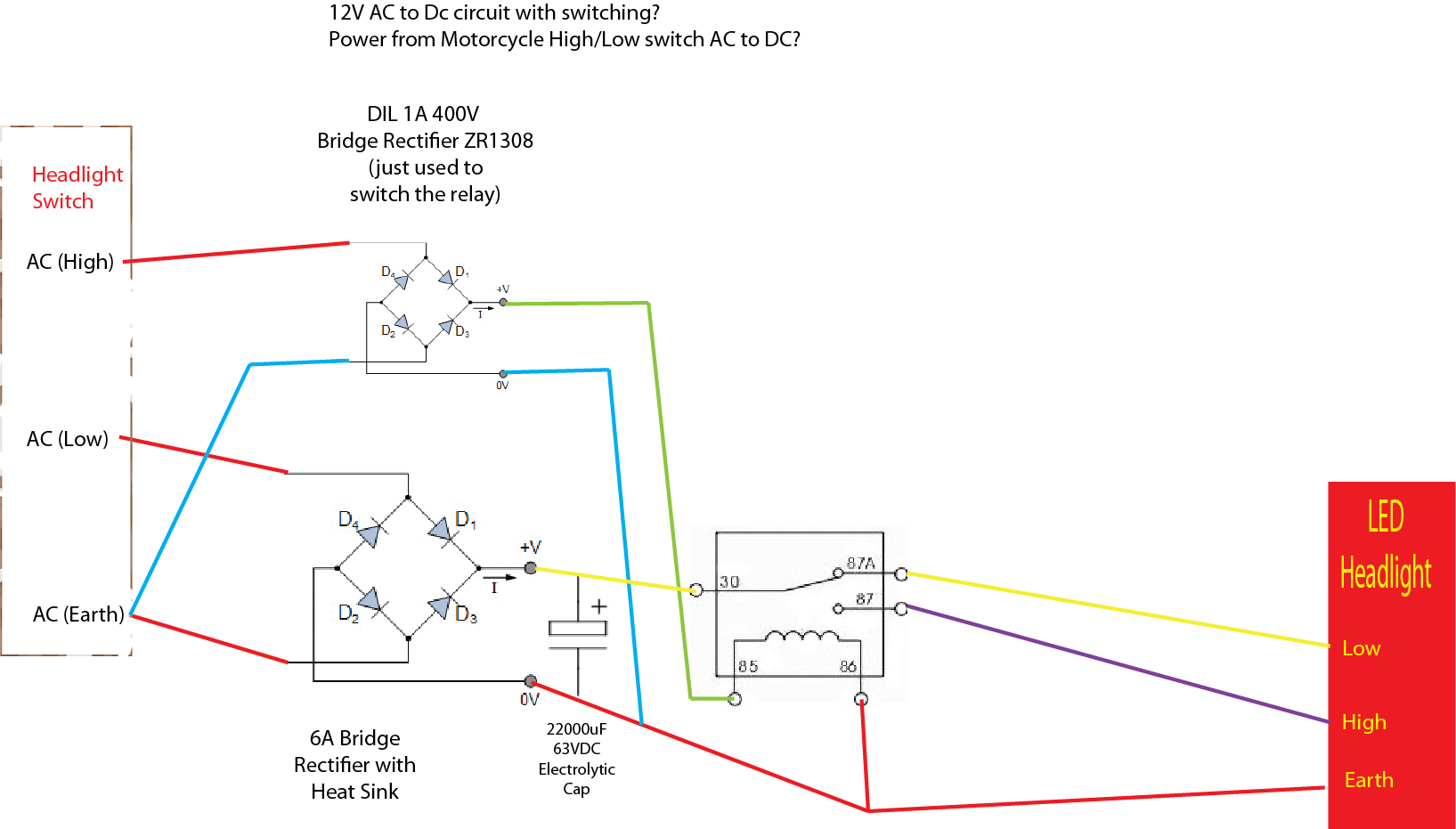

I'm trying to convert a 12VAC circuit to 12VDC, but the trick is, it has to output High and Low on an LED Headlight using the original switch. I'm trying to build a 'plug and play' unit to replace the current weak AC Globe. The LED draws from 1.5 to 4 amps depending on which one I use.

I've drawn a rough circuit of what I'm thinking but not sure about the eatrh/AC side? Note there are two bridge rectifiers, one is to convert the higher current for the light, the other just converts a couple of hundred milliamps to switch the relay.

Thoughts? Am I on the right track or miles off?

I'm trying to convert a 12VAC circuit to 12VDC, but the trick is, it has to output High and Low on an LED Headlight using the original switch. I'm trying to build a 'plug and play' unit to replace the current weak AC Globe. The LED draws from 1.5 to 4 amps depending on which one I use.

I've drawn a rough circuit of what I'm thinking but not sure about the eatrh/AC side? Note there are two bridge rectifiers, one is to convert the higher current for the light, the other just converts a couple of hundred milliamps to switch the relay.

Thoughts? Am I on the right track or miles off?