TheJay

Member

Hey everyone, it's really hard to get the alignment right with a guillotine and when I tried placing a torch underneath the paper, it made the job much easier as I had a visible line to guide me.

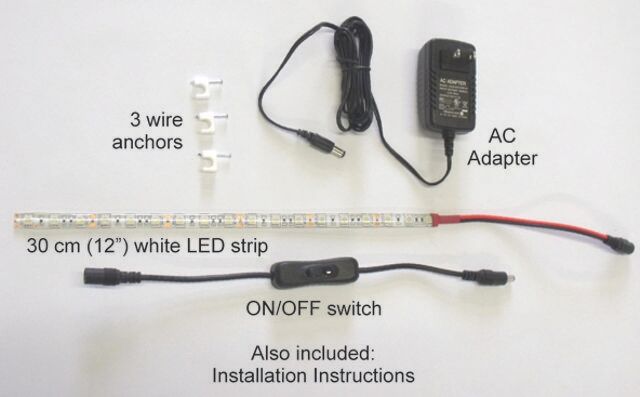

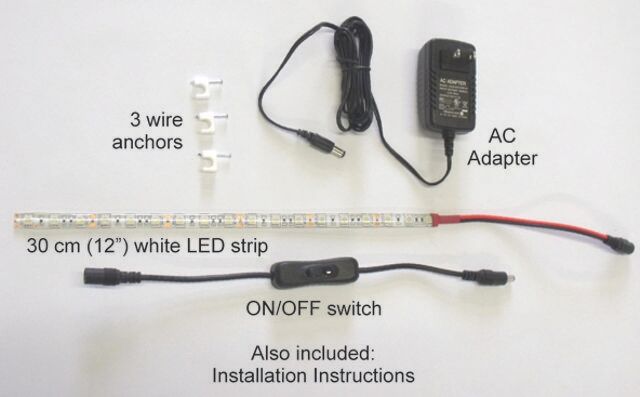

I need a bracket that can be mounted to the side of the guillotine allowing an LED strip to face upwards. Whilst looking at LED profiles, I came across this and it's a kit, kind of like I imagined when I started looking.

Does anyone know if all of these bits can be obtained individually from somewhere like eBay?

I'm ready to do some of it myself if necessary, as long as I can get the right components.

I saw a review saying the light wasn't bright enough, but that appears to be because the light was facing outwards rather than up and so the bracket I get needs to run the length of the blade, mounted to the base just under the lowest point the blade reaches when fully engaged.

I need a bracket that can be mounted to the side of the guillotine allowing an LED strip to face upwards. Whilst looking at LED profiles, I came across this and it's a kit, kind of like I imagined when I started looking.

Does anyone know if all of these bits can be obtained individually from somewhere like eBay?

I'm ready to do some of it myself if necessary, as long as I can get the right components.

I saw a review saying the light wasn't bright enough, but that appears to be because the light was facing outwards rather than up and so the bracket I get needs to run the length of the blade, mounted to the base just under the lowest point the blade reaches when fully engaged.