MD MUBDIUL HASAN

Member

Hello there,

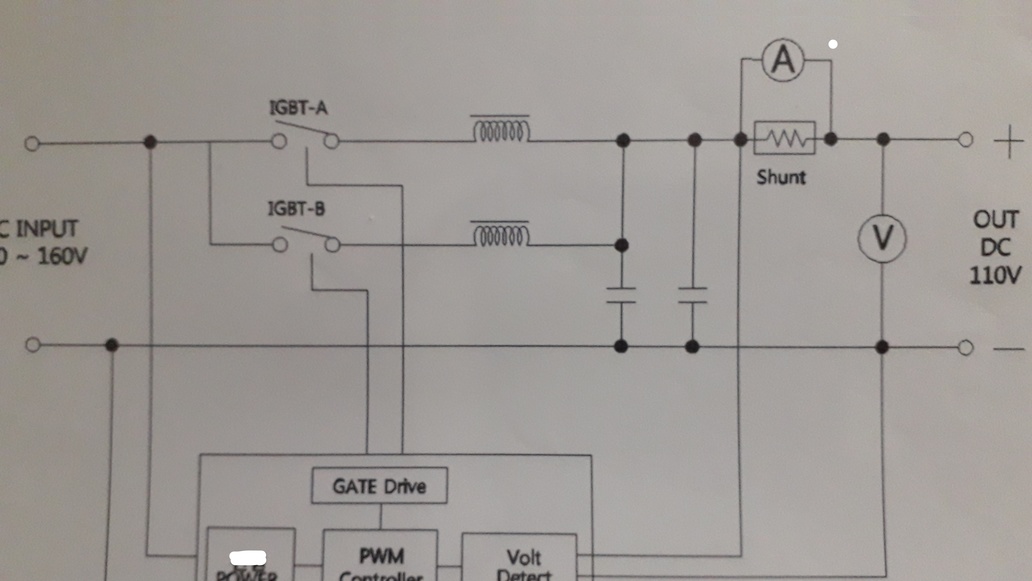

Anser this post who knows Power Electronics well.

Take a look my buck conveter in attachment.

People may called it "Dropper'

It has following properties,

1. Input is 120 to 160 volt DC/ 30 Amp.

2. Output must be 110volt/30 amp(maximum). +- 5% regulation( contineous output should be 20 amps)

3. Isolated in both input and output circuit.

4. Shunt sensing.

5. proper feedback.

6. 2 switches gets OFF/ON alternately.

7. May be soft switching.

8. May be 90% efficient.

I am thinking to modify it because bulky reactor/coupled inductor.

It has high current application.

kindly suggest a design that has

1. Less switching losss.

2. Less stress on switch.

3. Less number of component.

4. ZVS or ZCS idea.

5. Suitable ripple minimization.

6. Suitable couple inductor design.

Anser this post who knows Power Electronics well.

Take a look my buck conveter in attachment.

People may called it "Dropper'

It has following properties,

1. Input is 120 to 160 volt DC/ 30 Amp.

2. Output must be 110volt/30 amp(maximum). +- 5% regulation( contineous output should be 20 amps)

3. Isolated in both input and output circuit.

4. Shunt sensing.

5. proper feedback.

6. 2 switches gets OFF/ON alternately.

7. May be soft switching.

8. May be 90% efficient.

I am thinking to modify it because bulky reactor/coupled inductor.

It has high current application.

kindly suggest a design that has

1. Less switching losss.

2. Less stress on switch.

3. Less number of component.

4. ZVS or ZCS idea.

5. Suitable ripple minimization.

6. Suitable couple inductor design.