ADWSystems

Member

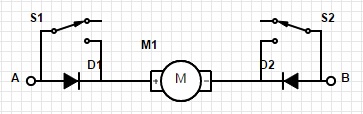

Someone else lead to me to this schematic.

There is a DC motor connected to a leadscrew. At either end of the travel there is a SPDT limit switch and diode. Power and ground are supplied at ports A and B. When the slide reaches the end of travel, the limit switch is tripped cutting power to the motor. When the polarity is reversed, power flows through the bypass diode and the closed switch at the opposite end and the slide moves the other direction. When the limit is reached, power is removed.

I have been trying to find a way tie into the switches to create a single output that signals the slide is in position. For Port A=12V, Port B=0V, the slide will travel left to right and I would really like to know when the limit switch is reached.

A couple of permitted items I have thought up:

1) The power will be removed from the motor once the slide is in position. The signal maybe lost, which is OK I already know it got there

2) If the solution results in a 1-0-1 pattern, that too would be fine. I would look for the 1-0 transition and then the 0-1 transition.

There is a DC motor connected to a leadscrew. At either end of the travel there is a SPDT limit switch and diode. Power and ground are supplied at ports A and B. When the slide reaches the end of travel, the limit switch is tripped cutting power to the motor. When the polarity is reversed, power flows through the bypass diode and the closed switch at the opposite end and the slide moves the other direction. When the limit is reached, power is removed.

I have been trying to find a way tie into the switches to create a single output that signals the slide is in position. For Port A=12V, Port B=0V, the slide will travel left to right and I would really like to know when the limit switch is reached.

A couple of permitted items I have thought up:

1) The power will be removed from the motor once the slide is in position. The signal maybe lost, which is OK I already know it got there

2) If the solution results in a 1-0-1 pattern, that too would be fine. I would look for the 1-0 transition and then the 0-1 transition.