All diodes including LED's have a threshold voltage, Vth ( at say 10% of rated current) , a rated forward voltage Vf @ If and the difference in voltage can be used to approximate the effective series resistance inside or ESR.

Having worked with thousands of different types of LED's, I have a rule of thumb that the ESR of the diode is inversely proportional to the power rating such that the product term is nearly constant across all good vendors and sizes. Poor quality ones will be higher ESR per Watt or higher Vf per Amp unless in series strings. It also varies with chemistry, process & wavelength and is not exact.

When testing be sure never to exceed 5V as this is the maximum reverse voltage for ALL LEDs. Even though the leakage is only 1uA for Red/Yellow and 10uW for small Blue/White, the current rises rapidly at -10V and the breakdown is catastrophic or wounds it like ESD with infant mortality.

Which brings up another issue ... Handling.

I only buy LED's with zener protection or design them back to back, if handling or stray transient fields are nearby. Of course how you handle them is your problem, since you can never guess which polarity your ESD will be on constant.

Anyhow, my Rule of Thumb is 1 Watt-Ohm (WΩ) for internal ESR which is included in the Ohm's Law curve for V vs I with an external current limiting resistor.

Once you establish ESR, Choosing the resistor is just Ohm's Law between Vth and Vf.

The problem is few understand this so they dont spec Vth only Vf, but you can memorize these values.

Vf is inversely proportional to the wavelength.

For High Bright (HB) LEDs

IR Vth 0.8 Vf=1.0

Red , Yellow Vth=1.8 Vf=2.0-2.3

Blue, White Vth=2.8 Vf=3.0~3.5

UV ....more

The older RED LEDS were a lower Vf due to the longer wavelength.

Epoxy 5mm LEDs are thermally insulated, so the standard is 20 mA .

SMD can much higher with thicker gold μwire bonds and better thermal resistance.

Current ratings are thus according to size & heatsink with large variations unlike epoxy encapsulated ones.

Use a large resistor like 2 or 3K to measure the voltage drop, I call Vth from 5V. ( Not 12 incase you reverse it)

You can extrapolate to Vth if you know the power rating then use Ohm's Law for the difference R that limits current.

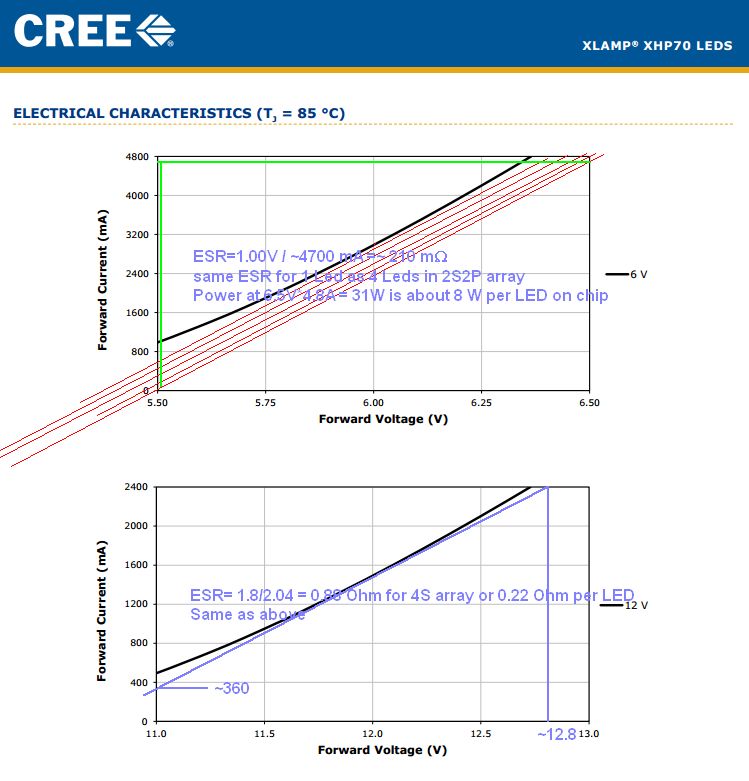

This is obvious a high powered array of LEDs on a chip. 4S means 4 in series and the upper one 2S2P ,, you can guess.