SimonTHK

Member

Hello electro people!

I have a jetski, and now something have burned in it twice, something that cost a student 150$ each time it happens. With all the great and fantastic help, I am sure I can build this myself. But I need the help

A similar jetski: **broken link removed**

The problem on my ski is that it burned the CDI ignition twice. This is kinda like a programable spark plug ignition.

Right now I look at this "guide": SportDevices. CDI Programmable Digital Ignition.

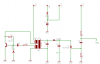

and it is the same picture I have put here with numbers, so its easy for me to ask and you to help.

It is not my idea to use the same microprocessor or follow this guide 100%, I just need to know what it is all about.

Please have in mind that I havtn studied much over a year.

Q1, number 1: Would you build such and ignition coil yourself? Or can it be bought? It has 200-300v primary and 30k v secondary.

Answear:

Q2: The guide is for one spark plug, my machine have two. I guess I could use the same ignition coil for both spark plugs, I just have to lead the current with a mosfet or what would you use?

Q3, number 6: I know that an ignition coil makes the spark plug spark when it discharges right? How does it disharge in this schematic? Through the thyristor? When RA2 (number 2) is high?

Q4: In this circuit the microprocessor should register the "pick up" pulse, have a delay time programmed and then make an output to the thyristor. Can anyone confirm this?

Q5, number 2: There are shown 2 diodes with a resistor. The right side is from the Uc to send an ignition signal right? What is the left side doing? I cant figure that out?

I have more quistions but lets start with these

but lets start with these

I have a jetski, and now something have burned in it twice, something that cost a student 150$ each time it happens. With all the great and fantastic help, I am sure I can build this myself. But I need the help

A similar jetski: **broken link removed**

The problem on my ski is that it burned the CDI ignition twice. This is kinda like a programable spark plug ignition.

Right now I look at this "guide": SportDevices. CDI Programmable Digital Ignition.

and it is the same picture I have put here with numbers, so its easy for me to ask and you to help.

It is not my idea to use the same microprocessor or follow this guide 100%, I just need to know what it is all about.

Please have in mind that I havtn studied much over a year.

Q1, number 1: Would you build such and ignition coil yourself? Or can it be bought? It has 200-300v primary and 30k v secondary.

Answear:

Q2: The guide is for one spark plug, my machine have two. I guess I could use the same ignition coil for both spark plugs, I just have to lead the current with a mosfet or what would you use?

Q3, number 6: I know that an ignition coil makes the spark plug spark when it discharges right? How does it disharge in this schematic? Through the thyristor? When RA2 (number 2) is high?

Q4: In this circuit the microprocessor should register the "pick up" pulse, have a delay time programmed and then make an output to the thyristor. Can anyone confirm this?

Q5, number 2: There are shown 2 diodes with a resistor. The right side is from the Uc to send an ignition signal right? What is the left side doing? I cant figure that out?

I have more quistions