agent420

New Member

So I'm building one of those 3d led cubes with an 8x8x8 matrix, 512 leds total.

I will be using an Atmel Mega1280 or similar AVR that provides enough io to control 64 individual leds (one plane), so multiplexing will be 64x8.

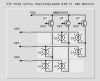

I need to switch power to a load consisting of a 64 leds (one plane), estimated power of 1.3A at 5V. I am trying to avoid the use of dozens of discrete devices, so I'm thinking of using 8 x 2803's to provide individual led control and some power mosfet like the irf510 or similar power transistor to control common rail supply. Can I use these as a high side switch like this? Can I use more common npn in this position, or does hi switching require pnp or pchannel fets?

**broken link removed**

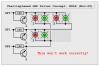

Alternately, if I use low side switching, do you think I can control the common rail by switching the 2803 grounds like this:

**broken link removed**

Thanks for any input you may have.

I will be using an Atmel Mega1280 or similar AVR that provides enough io to control 64 individual leds (one plane), so multiplexing will be 64x8.

I need to switch power to a load consisting of a 64 leds (one plane), estimated power of 1.3A at 5V. I am trying to avoid the use of dozens of discrete devices, so I'm thinking of using 8 x 2803's to provide individual led control and some power mosfet like the irf510 or similar power transistor to control common rail supply. Can I use these as a high side switch like this? Can I use more common npn in this position, or does hi switching require pnp or pchannel fets?

**broken link removed**

Alternately, if I use low side switching, do you think I can control the common rail by switching the 2803 grounds like this:

**broken link removed**

Thanks for any input you may have.

Last edited: