Hi everyone, i was wondering to make a proyect like this one: Smart Plug Proyect

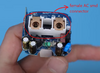

Just for electronics learning purposes. However, i am having problems in finding the differents parts of the female connector (the gnd metalic thing, and the european smd AC connector).

Do anyone know the exact reference of this pieces or closest one? I have been searching in mouser and digikey, but i didn´t be able to find anything similar.

If something isn´t explained cleary pls let me know what is confusing ...

Thanks for the help guys, hope someone can help me

Just for electronics learning purposes. However, i am having problems in finding the differents parts of the female connector (the gnd metalic thing, and the european smd AC connector).

Do anyone know the exact reference of this pieces or closest one? I have been searching in mouser and digikey, but i didn´t be able to find anything similar.

If something isn´t explained cleary pls let me know what is confusing ...

Thanks for the help guys, hope someone can help me