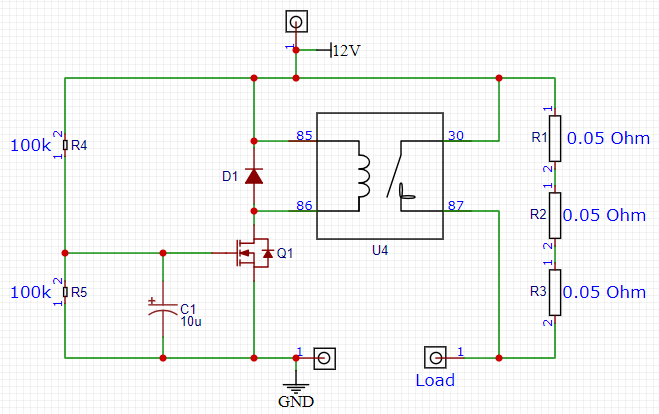

I am trying to design a soft start circuit for a 12V high current load. The 12V power source is a large 240Ah LiFePO4 battery with a BMS that is cutting out because the initial load of the ARB Twin compressor is drawing a peak in-rush current of nearly 200 amps. The BMS is rated at 100 Amps constant or 150 Amps momentary.

I have made an attempt to spec components based on a simple mosfet, relay and power resistor design but it's not working. Ie I introduce the circuit into the load but it makes no differnce and the bms continues to kick in and disable the battery as soon as i turn on the ARB Twin Compressor.

I'm not sure if it's dodgy components (because I roasted them when soldering) or incorrect component specs.

I basically wanted to restrict the load current to 80 Amps until the relay is closed. So i chose 3 x 0.05 Ohm resistors. I've tried both 10 and 22 uf caps and when i test on the bench, i do get about a one second or two second delay before I hear the relay switch but when i install into the actual load (it's in my 4wd), as soon as i turn on the ARB Twin air compressor the BMS kicks in. This seems to not even be after one or two seconds but immediately as if the greater than 150 Amps is still being drawn.

I'm hoping someone can at least confirm the design is sound or not?

C1

50YXM10MEFRTA5X11 CAP ALUM 10UF 20% 50V TH

https://www.rubycon.co.jp/en/catalog/e_pdfs/aluminum/e_yxm.pdf

D1

1N4002-E3/54 DIODE GEN PURP 100V 1A DO204AL

https://www.vishay.com/docs/88503/1n4001.pdf

Q1

FQD1N80TM MOSFET N-CH 800V 1A DPAK

https://www.onsemi.com/pdf/datasheet/fqu1n80-d.pdf

R1, R2, R3

FCSL110R050FER RES 0.05 OHM 5W 4320 WIDE

https://www.ohmite.com/assets/docs/res_fcsl.pdf?r=false

R4, R5

RNC55J1003BSRE6 RES 100K OHM 1/8W .1% AXIAL

https://www.vishay.com/docs/31025/erc.pdf

U4

DG85D-7021-75-1012 12V dc Coil Non-Latching Relay SPNO PCB Mount, Single Pole

https://docs.rs-online.com/3ffe/A700000007295110.pdf

I have made an attempt to spec components based on a simple mosfet, relay and power resistor design but it's not working. Ie I introduce the circuit into the load but it makes no differnce and the bms continues to kick in and disable the battery as soon as i turn on the ARB Twin Compressor.

I'm not sure if it's dodgy components (because I roasted them when soldering) or incorrect component specs.

I basically wanted to restrict the load current to 80 Amps until the relay is closed. So i chose 3 x 0.05 Ohm resistors. I've tried both 10 and 22 uf caps and when i test on the bench, i do get about a one second or two second delay before I hear the relay switch but when i install into the actual load (it's in my 4wd), as soon as i turn on the ARB Twin air compressor the BMS kicks in. This seems to not even be after one or two seconds but immediately as if the greater than 150 Amps is still being drawn.

I'm hoping someone can at least confirm the design is sound or not?

C1

50YXM10MEFRTA5X11 CAP ALUM 10UF 20% 50V TH

https://www.rubycon.co.jp/en/catalog/e_pdfs/aluminum/e_yxm.pdf

D1

1N4002-E3/54 DIODE GEN PURP 100V 1A DO204AL

https://www.vishay.com/docs/88503/1n4001.pdf

Q1

FQD1N80TM MOSFET N-CH 800V 1A DPAK

https://www.onsemi.com/pdf/datasheet/fqu1n80-d.pdf

R1, R2, R3

FCSL110R050FER RES 0.05 OHM 5W 4320 WIDE

https://www.ohmite.com/assets/docs/res_fcsl.pdf?r=false

R4, R5

RNC55J1003BSRE6 RES 100K OHM 1/8W .1% AXIAL

https://www.vishay.com/docs/31025/erc.pdf

U4

DG85D-7021-75-1012 12V dc Coil Non-Latching Relay SPNO PCB Mount, Single Pole

https://docs.rs-online.com/3ffe/A700000007295110.pdf

Last edited: