I am building a SCUBA torch using a piezo switch (these work well underwater) and two LED heads.

The sequence I am after is;

First press...LED 1 on,

Second press... both LED 1 & 2 on.

Third press...both off.

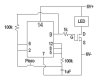

The circuit in my current torch has only one LED and uses a 555timer to toggle the LED on/off via the piezo. The 555 output operates a FET allowing 1amp to flow.

Do I need to source a programmed chip or can this circuit be made using ordinary non-programmable parts?

Regards

Mac

The sequence I am after is;

First press...LED 1 on,

Second press... both LED 1 & 2 on.

Third press...both off.

The circuit in my current torch has only one LED and uses a 555timer to toggle the LED on/off via the piezo. The 555 output operates a FET allowing 1amp to flow.

Do I need to source a programmed chip or can this circuit be made using ordinary non-programmable parts?

Regards

Mac