Hi all,

Newbie here as i'm just getting back into electronics and looking for some guidance in modifying an existing off the shelf circuit.

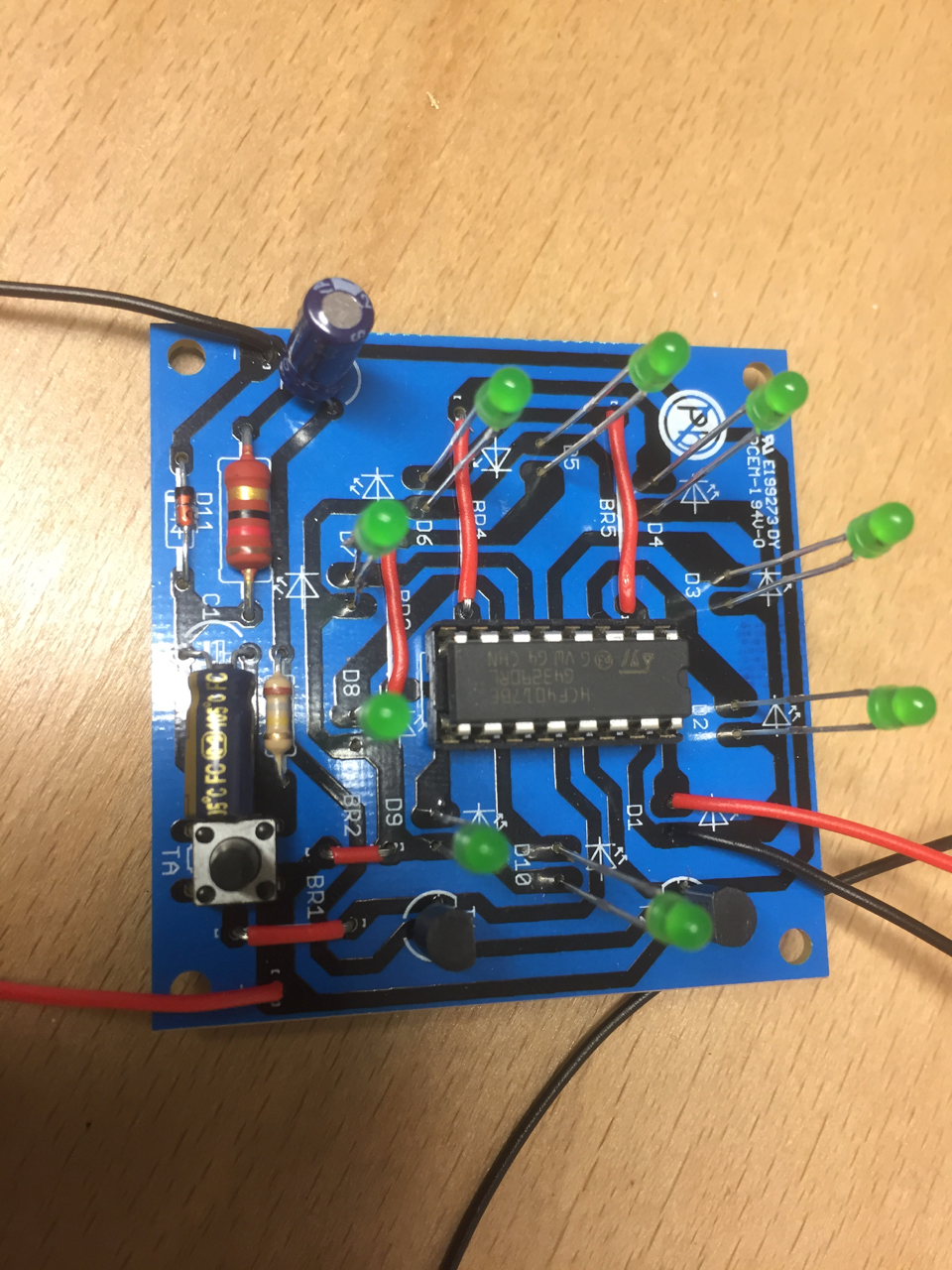

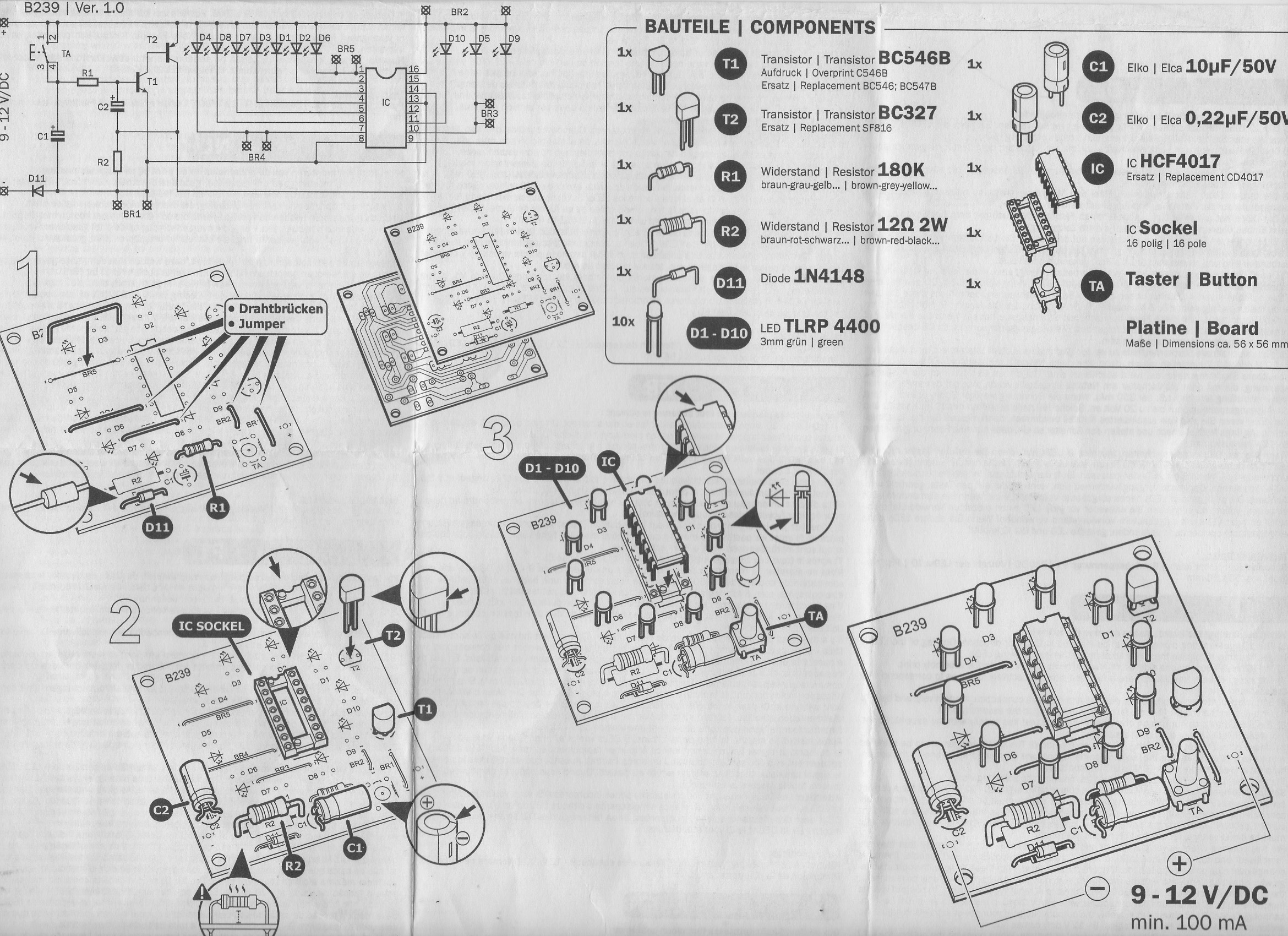

The circuit is an Electronic wheel of Fortune link: https://www.kemo-electronic.de/en/Hobby-School/B239-Electronic-wheel-of-fortune.php

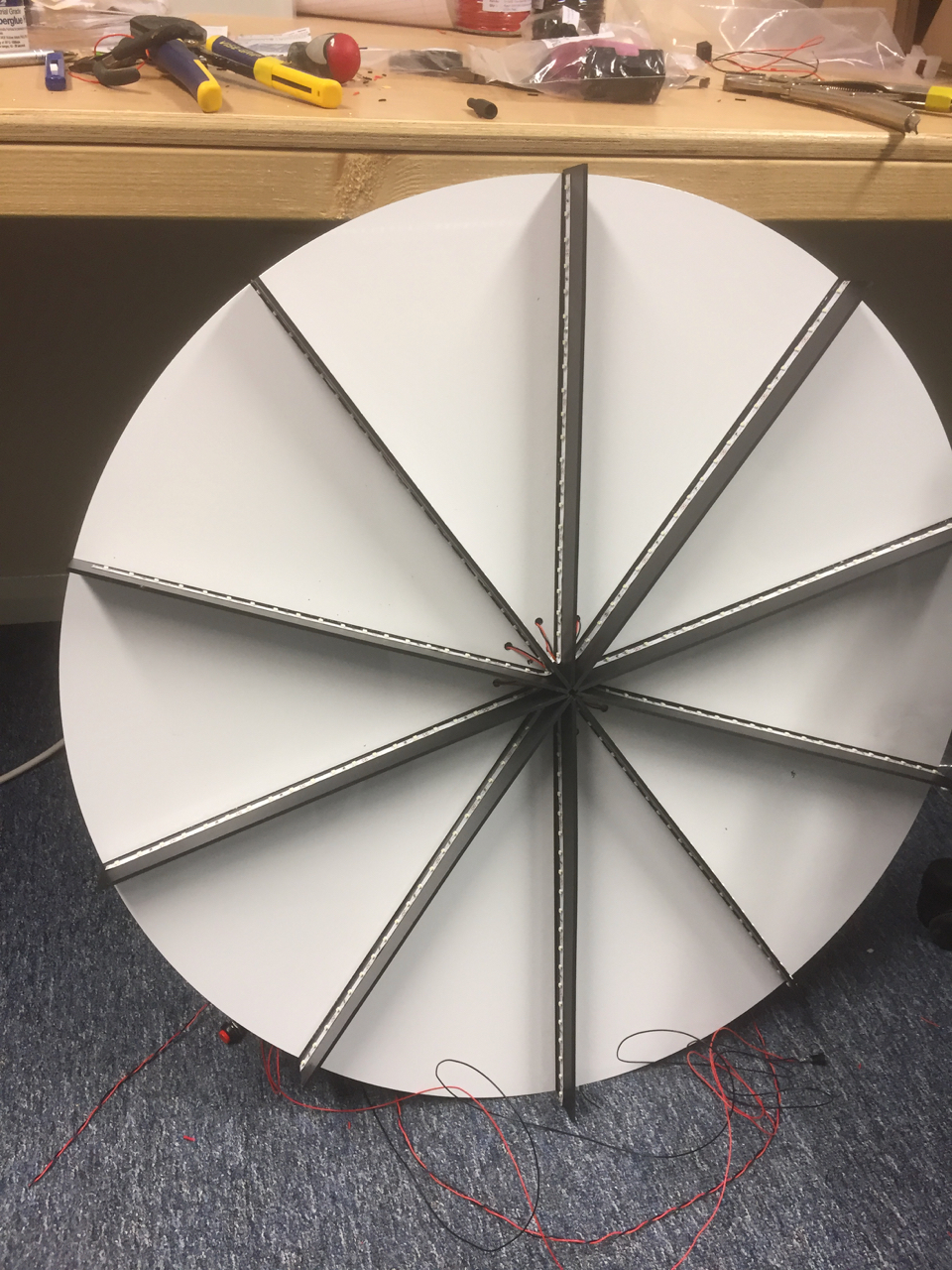

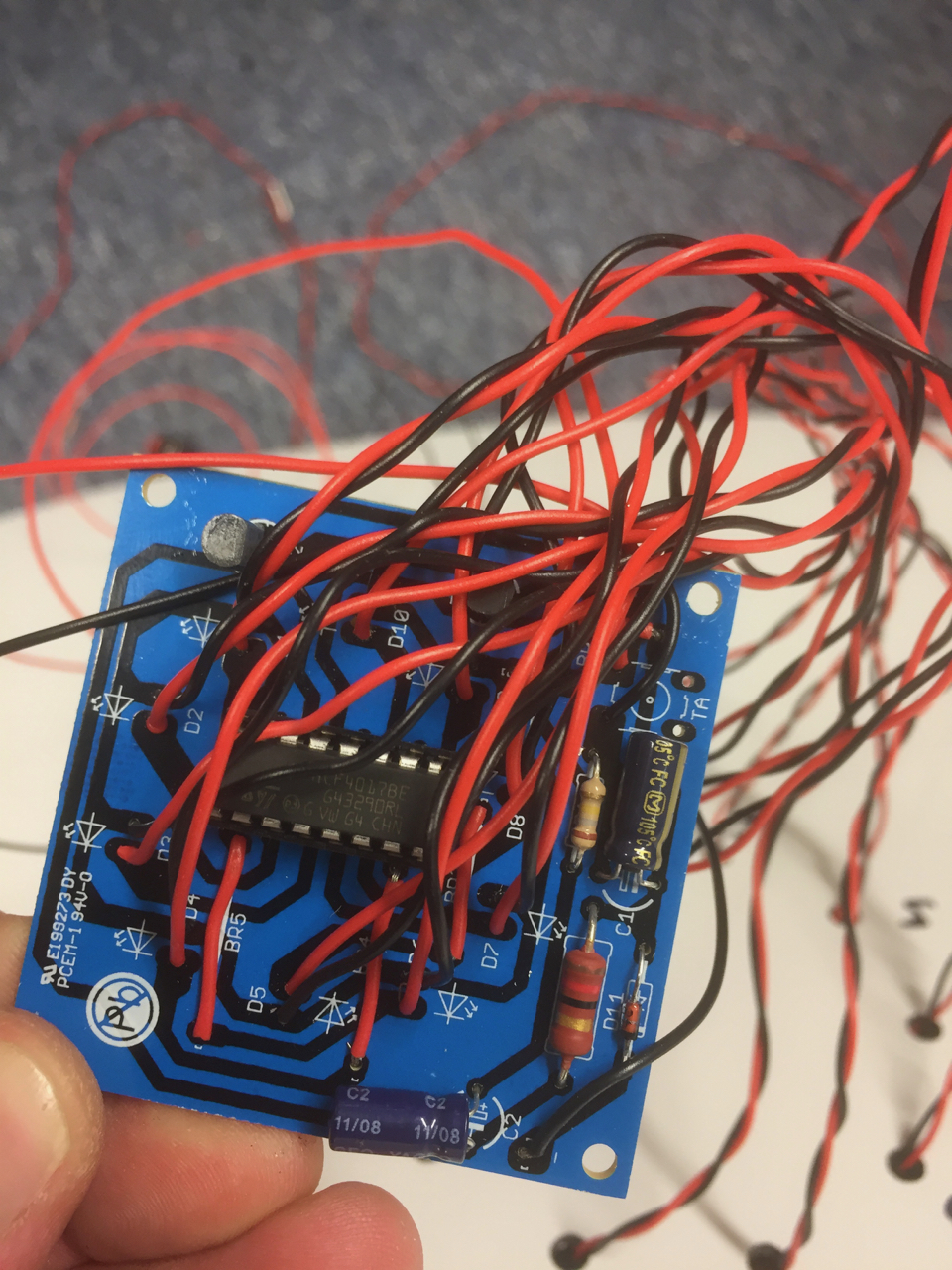

What i'm trying to achieve is to upscale the circuit to drive lengths of LED tape (12v 4.8W 6000k White 60 x 3528 / metre LED tape IP20 rated at 4.8w p/M. Using a 12V 3Amp power supply which are then fixed into a segmented unit which will have a printed acrylic face on the front.

Currently the circuit works illuminating all of the LEDs with one unlit one spinning round when the button is depressed and released which then gradually comes to a halt. Obviously this is quite a draw on the power driving 10 x 720mm lengths of LED tape (see attached picture of the wheel) so I would like the LEDs to be brighter than they currently are.. Therefore, what I would like it to do is only have one LED/tape strip lit / spinning and coming to a halt. Also the speed at which it spins I would like to slow down, would I be correct in that this is controlled via a capacitor / transistor connected to pin 14 of the HCF4017 Decade Counter if so how can I slow this spinning down as from searching on this IC it is usually placed with a timer chip / variable resistor to control the speed of the counter?

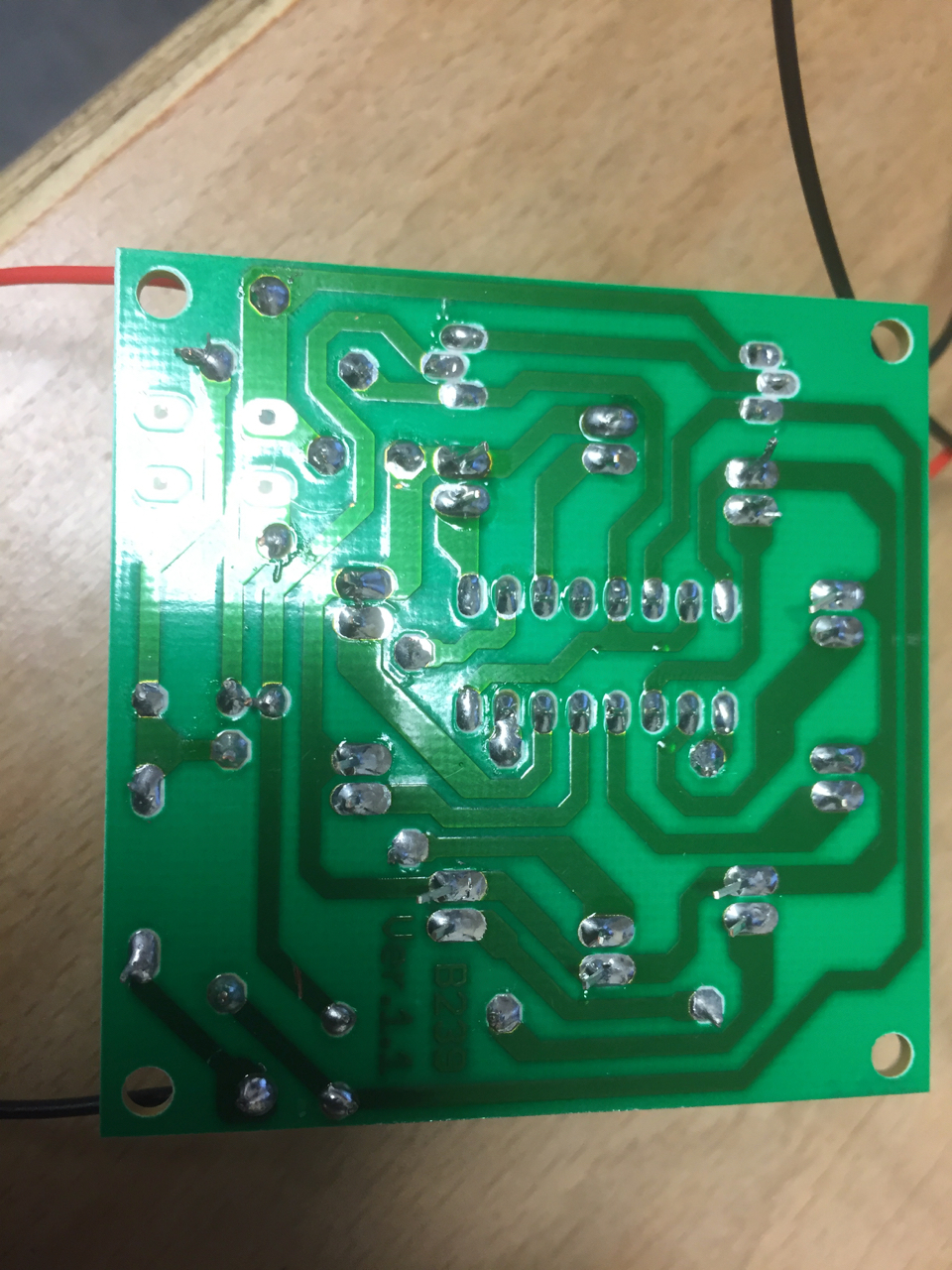

I have attached a couple of photos of what I have done so far and schematic.

Many thanks in advance for any guidance on this.

Cheers

Stu

Newbie here as i'm just getting back into electronics and looking for some guidance in modifying an existing off the shelf circuit.

The circuit is an Electronic wheel of Fortune link: https://www.kemo-electronic.de/en/Hobby-School/B239-Electronic-wheel-of-fortune.php

What i'm trying to achieve is to upscale the circuit to drive lengths of LED tape (12v 4.8W 6000k White 60 x 3528 / metre LED tape IP20 rated at 4.8w p/M. Using a 12V 3Amp power supply which are then fixed into a segmented unit which will have a printed acrylic face on the front.

Currently the circuit works illuminating all of the LEDs with one unlit one spinning round when the button is depressed and released which then gradually comes to a halt. Obviously this is quite a draw on the power driving 10 x 720mm lengths of LED tape (see attached picture of the wheel) so I would like the LEDs to be brighter than they currently are.. Therefore, what I would like it to do is only have one LED/tape strip lit / spinning and coming to a halt. Also the speed at which it spins I would like to slow down, would I be correct in that this is controlled via a capacitor / transistor connected to pin 14 of the HCF4017 Decade Counter if so how can I slow this spinning down as from searching on this IC it is usually placed with a timer chip / variable resistor to control the speed of the counter?

I have attached a couple of photos of what I have done so far and schematic.

Many thanks in advance for any guidance on this.

Cheers

Stu