I've been repairing some of these:- https://www.redlion.net/product/225-6-digit-led-counter and they have the quite neat feature that the supply voltage is 22 - 240 V, AC or DC.

They use these:- https://www.power.com/sites/default/files/product-docs/top242.250.pdf for the flyback controller. In order to work over such a wide voltage range, the built-in shunt regulator in the flyback controller isn't used, and there is an external shunt regulator with a buffer transistor instead.

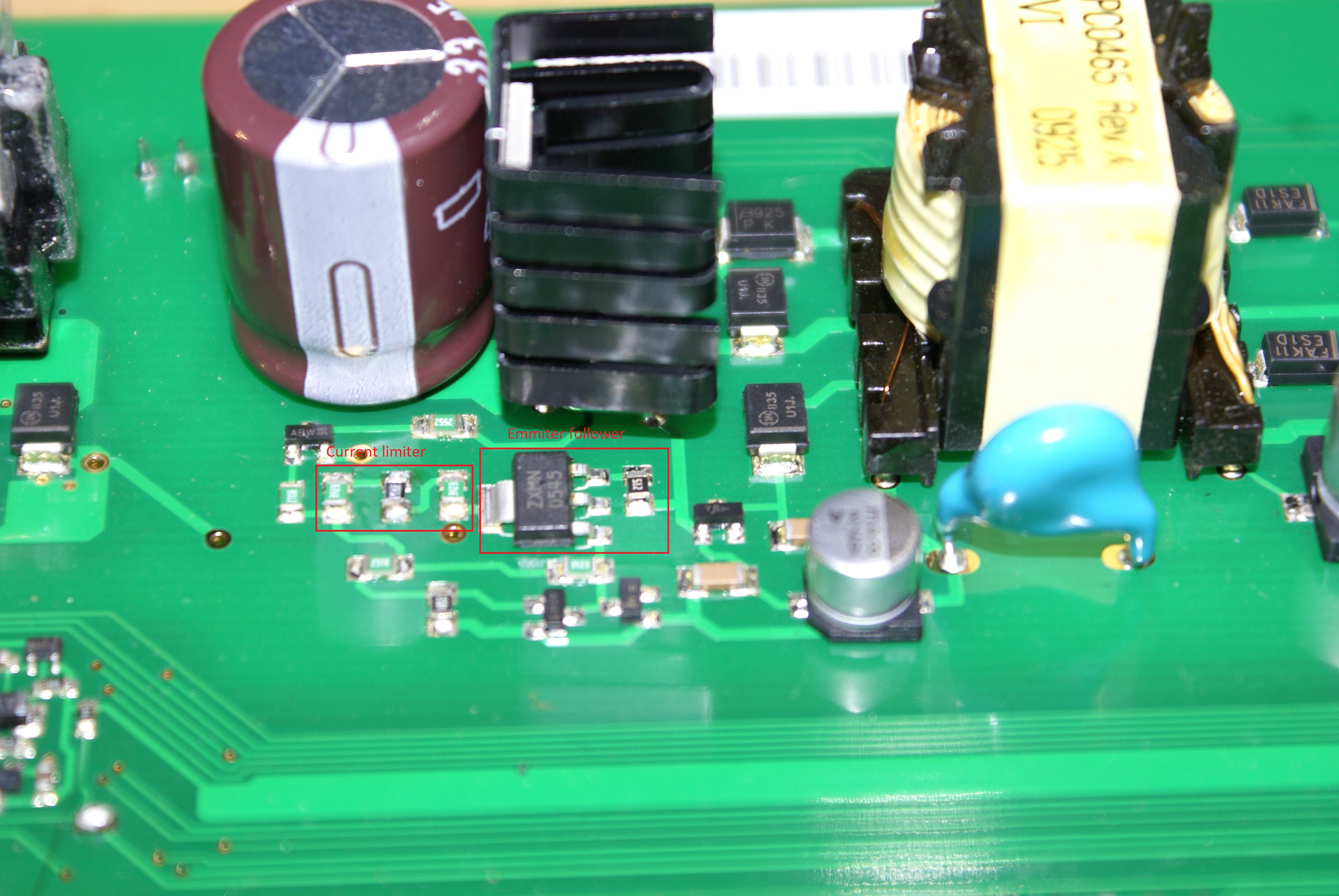

The current limiter is made of three 0805 resistors, each of 392 kOhm. I assume that three resistors are used to keep the voltage across each one within the rating for the resisotors. The power is very small at around 30 mW when on 240 V ac. The resistors appeared to be precision ones, and I can't think of any reason for that.

On all of the units that had failed, one of the three resistors had failed open circuit. There was no visible fault. The photo was taken after I had replaced the resistor.

Has anyone got any idea what caused the resistors to fail?

They use these:- https://www.power.com/sites/default/files/product-docs/top242.250.pdf for the flyback controller. In order to work over such a wide voltage range, the built-in shunt regulator in the flyback controller isn't used, and there is an external shunt regulator with a buffer transistor instead.

The current limiter is made of three 0805 resistors, each of 392 kOhm. I assume that three resistors are used to keep the voltage across each one within the rating for the resisotors. The power is very small at around 30 mW when on 240 V ac. The resistors appeared to be precision ones, and I can't think of any reason for that.

On all of the units that had failed, one of the three resistors had failed open circuit. There was no visible fault. The photo was taken after I had replaced the resistor.

Has anyone got any idea what caused the resistors to fail?