I have a Bosch BCH625KTGB vacuum cleaner on which the retained charge has deteriorated to the point of no longer being useful. A Bosch replacement 'Accumulator module' sells for a higher figure £192 than a new (discounted) complete cleaner £169.00, so I opted to replace the cells.

Purchased the cells; disassembled the unit, disconnected (cut) the battery from the logic board; removed the existing cells and replaced them with new ones.

The battery voltage is 25.2V, and the voltages at the BMS connector all step up in 4.2V steps. All exactly as it should be.

Reinstalled the board and made all the connections except battery +ve; checked everything and then touched the positive to its connection point on the board. The motor roared into life.

Problem: the switch was in the off position!

No smoke. No physical signs that anything is wrong. The logic board is simply sending power to the motor when the switch is off. Even when when the connector to the switch is entirely disconnected. Everything smacks of a very confused microcontroller.

The logic board contains two parts.

1) the BMS for charging.

2) a microprocessor (MEGA328P) for controlling the 3 'power' levels -- motor speed -- and sensing a 'bag full' condition via a pressure sensor.

I found reference -- only after I had a problem -- to someone suggesting in a comment to a youtube video, that the eeprom might be vulnerable (in some unspecified way) to disconnection:

So, what are my chances of recovering the unit? Given I don't have any test equipement beyond a multimeter and there are no service manuals available as far as I can tell from my searching.

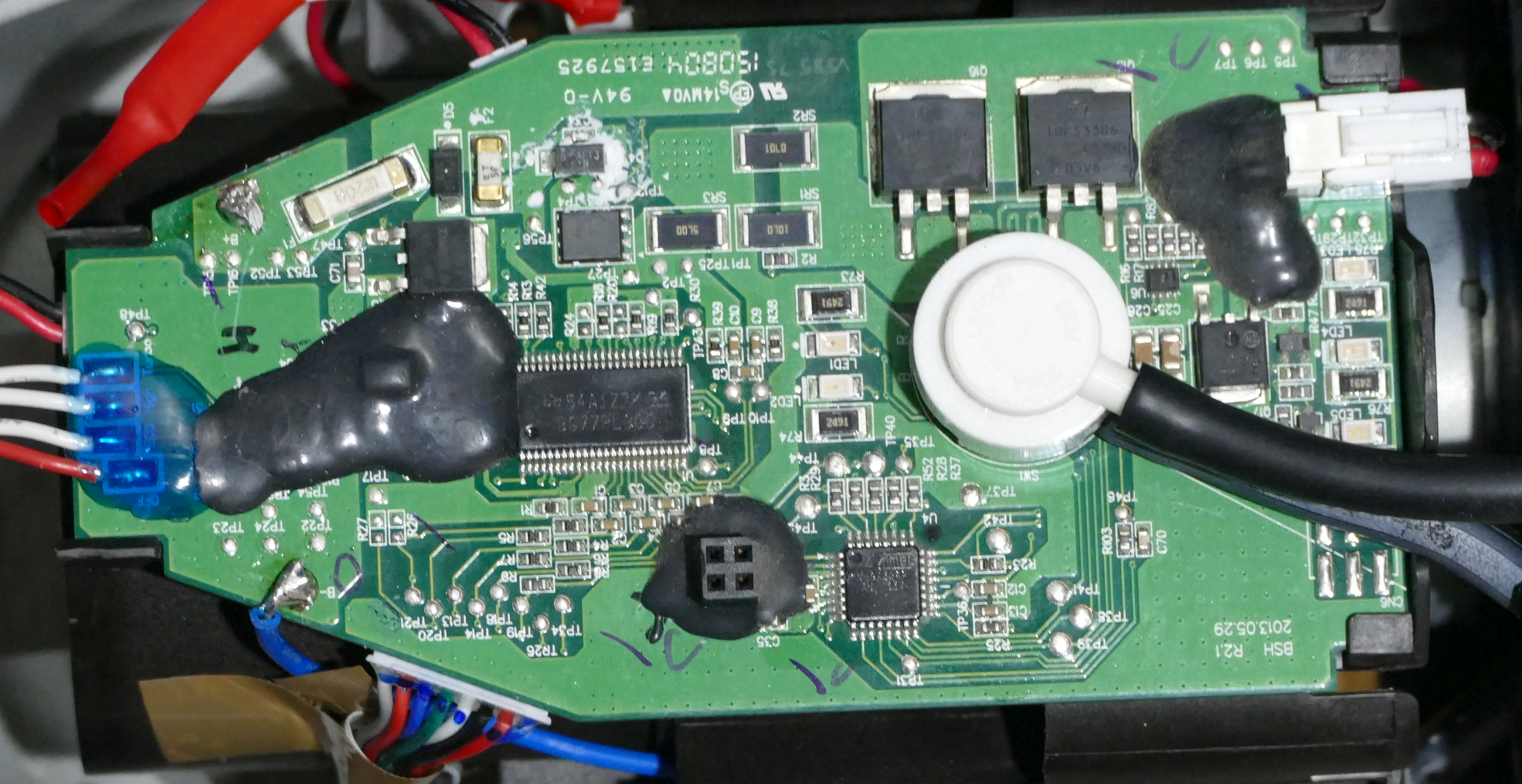

Here's a photo of the board:

The large chip in the middle is a TI BQ77PL900 5-10 cell Li-ion Battery protection & AFE.

The smaller square chip bottom middle is a MEGA328P µCPU.

Both chips have I2C interfaces and (I assume) the 4 pin plug between them is for that.

The big white thing with the tubes is the pressure sensor.

The battery power comes in via the thick blue cable soldered to B- bottom left; and the cable protected by the heat shrink sleeve top left that should be connected to B+

Power to the motor leaves via the white connector top right.

The 3 white and a red cable left connect to the 3 position power switch in the handle.

The black&red wires coming from a connector just above them, and behind the board are the input from the 30V/500mA half-wave rectifying wall wart.

It appears that both the BMS chip and the µCPU have embedded eeproms. Its not clear which one the youtube comment was referring to.

Purchased the cells; disassembled the unit, disconnected (cut) the battery from the logic board; removed the existing cells and replaced them with new ones.

The battery voltage is 25.2V, and the voltages at the BMS connector all step up in 4.2V steps. All exactly as it should be.

Reinstalled the board and made all the connections except battery +ve; checked everything and then touched the positive to its connection point on the board. The motor roared into life.

Problem: the switch was in the off position!

No smoke. No physical signs that anything is wrong. The logic board is simply sending power to the motor when the switch is off. Even when when the connector to the switch is entirely disconnected. Everything smacks of a very confused microcontroller.

The logic board contains two parts.

1) the BMS for charging.

2) a microprocessor (MEGA328P) for controlling the 3 'power' levels -- motor speed -- and sensing a 'bag full' condition via a pressure sensor.

I found reference -- only after I had a problem -- to someone suggesting in a comment to a youtube video, that the eeprom might be vulnerable (in some unspecified way) to disconnection:

I successfully replaced the batteries in my unit. It is very important to read the previous comments. My unit was working OK, so as a precaution I decided to save the content of the EEPROM before disconnecting the cells. Some things to add: It looks the microcontroller is running at 3.3V which is cut off after like 10 seconds after switching off the cleaner. When using my adapter I provided externally this 3.3V to the power rail (TP 2 pad). It looks it causes no damage to it. I used MPLAB X to download the EEPROM and saved it as a text file. Fortunately I did not need it. I disconnected the black negative terminal first, then the wide battery connector and finally the red positive terminal. After spot welding the new cells I reconnected them in the reverse order.

So, what are my chances of recovering the unit? Given I don't have any test equipement beyond a multimeter and there are no service manuals available as far as I can tell from my searching.

Here's a photo of the board:

The large chip in the middle is a TI BQ77PL900 5-10 cell Li-ion Battery protection & AFE.

The smaller square chip bottom middle is a MEGA328P µCPU.

Both chips have I2C interfaces and (I assume) the 4 pin plug between them is for that.

The big white thing with the tubes is the pressure sensor.

The battery power comes in via the thick blue cable soldered to B- bottom left; and the cable protected by the heat shrink sleeve top left that should be connected to B+

Power to the motor leaves via the white connector top right.

The 3 white and a red cable left connect to the 3 position power switch in the handle.

The black&red wires coming from a connector just above them, and behind the board are the input from the 30V/500mA half-wave rectifying wall wart.

It appears that both the BMS chip and the µCPU have embedded eeproms. Its not clear which one the youtube comment was referring to.

Last edited: