Hey everyone,

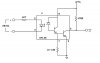

I'm wondering what would be the easiest way of converting a 28v signal to 'high' logic level for mcu.

I've read somewhere that pics have an internal diode clamp or something so I would only need a series resistor to read the 28v as '1'.

Would these diodes tolerate 28v ?

Is there a better way to convert the 28v to '1' for the pic ?

Thanks in advance, Mike.

I'm wondering what would be the easiest way of converting a 28v signal to 'high' logic level for mcu.

I've read somewhere that pics have an internal diode clamp or something so I would only need a series resistor to read the 28v as '1'.

Would these diodes tolerate 28v ?

Is there a better way to convert the 28v to '1' for the pic ?

Thanks in advance, Mike.