AllenPitts

Member

Hello ETO,

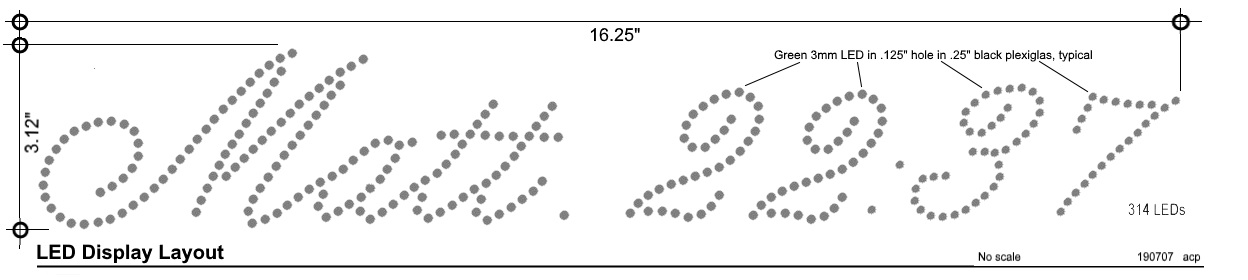

Working on a motion detector (PIR) actuated LED display

w 300 lights. Using 3 mm LED Mouser #: 604-WP710A10PGT

mounted in plexiglas operated by Maxim 7129 IC in

a custom designed PCB.

The question is how to connect the PCB to the LEDs.

At the PCB using Mouser 571_282834-8, TE Connectivity

Fixed terminal blocks. The terminal blocks

https://www.mouser.com/ProductDetai...cu6/tyhQV/GlIyync%2BR5zJOVGuWWFlMGm6TZ9uXIA==

while a bit expensive

work great because the connector screws down onto

the wire and provides good, firm connections.

The issue is the connection to the LEDs.

Have received :

Mouser #: 593-CNXBE4112

Mfr. #: CNX_B_E_4_1_12

Desc.: VCC Lighting Cables Lighting Cables 3MM PNL CNXBE4112

https://www.mouser.com/ProductDetai...Ikqup3QUmz/Q8k7gBr/4sqzV6M1gjuel%2B5IRrbvjg==

and

Mouser #: 523-SSL11J2LJ0B22A04

Mfr. #: SSL11-J2LJ0-B22A04

Desc.: Amphenol Lighting Cables Lighting Cables SSL1.1WIRE ASSY,WITH W2B LOCK

https://www.mouser.com/ProductDetai...a2WeR3g4GXWcnccVVD3Vb3JJEFGSvolicLooHaVVZ2WTA

Using the VCC CNXBX4112 it is often difficult to get the

LED leads to fit down into the header. See attached photo

marked 'LED One'.

![[IMG] [IMG]](https://www.allenpitts.com/electronics/Matt_22_37/LED_to_PCB_Connx_190706_1_sm.jpg)

In that photo the header marked 2.2.2 sits

down properly on the LED leads. The other two headers on the

right, like many others, even after fitting and refitting for

five or ten minutes will not go down onto the LED leads.

When the leads won't go all the way down on the LED lead,

if even touched slightly, will some times disconnect.

The wire coming out of the terminal block could be soldered to the

LED lead but that would be 600 solders. Will avoid if possible.

So purchased the Amphenol hoping to get an easier more, solid

connection at the LED, like the connx at the terminal blocks,

which are pretty easy, and very stable.

![[IMG] [IMG]](https://www.allenpitts.com/electronics/Matt_22_37/LED_to_PCB_Connx_190706_2_sm.jpg)

Hoped the Amphenol would solved the problem with fitting the header onto

the LED lead. But although the leads go into the header easier, the header

does not conduct through the LED to make the LED light.

See GIF marked LED Three.

![[IMG] [IMG]](https://www.allenpitts.com/electronics/Matt_22_37/LED_to_PCB_Connx_190706_3_sm.JPG)

Is there another lighting cable that would go from the

terminal blocks to the LED leads?

![[IMG] [IMG]](https://www.allenpitts.com/electronics/Matt_22_37/LED_to_PCB_Connx_190706_4_sm.jpg)

Thanks.

Allen Pitts, Dallas Texas

Working on a motion detector (PIR) actuated LED display

w 300 lights. Using 3 mm LED Mouser #: 604-WP710A10PGT

mounted in plexiglas operated by Maxim 7129 IC in

a custom designed PCB.

The question is how to connect the PCB to the LEDs.

At the PCB using Mouser 571_282834-8, TE Connectivity

Fixed terminal blocks. The terminal blocks

https://www.mouser.com/ProductDetai...cu6/tyhQV/GlIyync%2BR5zJOVGuWWFlMGm6TZ9uXIA==

while a bit expensive

work great because the connector screws down onto

the wire and provides good, firm connections.

The issue is the connection to the LEDs.

Have received :

Mouser #: 593-CNXBE4112

Mfr. #: CNX_B_E_4_1_12

Desc.: VCC Lighting Cables Lighting Cables 3MM PNL CNXBE4112

https://www.mouser.com/ProductDetai...Ikqup3QUmz/Q8k7gBr/4sqzV6M1gjuel%2B5IRrbvjg==

and

Mouser #: 523-SSL11J2LJ0B22A04

Mfr. #: SSL11-J2LJ0-B22A04

Desc.: Amphenol Lighting Cables Lighting Cables SSL1.1WIRE ASSY,WITH W2B LOCK

https://www.mouser.com/ProductDetai...a2WeR3g4GXWcnccVVD3Vb3JJEFGSvolicLooHaVVZ2WTA

Using the VCC CNXBX4112 it is often difficult to get the

LED leads to fit down into the header. See attached photo

marked 'LED One'.

![[IMG] [IMG]](https://www.allenpitts.com/electronics/Matt_22_37/LED_to_PCB_Connx_190706_1_sm.jpg)

In that photo the header marked 2.2.2 sits

down properly on the LED leads. The other two headers on the

right, like many others, even after fitting and refitting for

five or ten minutes will not go down onto the LED leads.

When the leads won't go all the way down on the LED lead,

if even touched slightly, will some times disconnect.

The wire coming out of the terminal block could be soldered to the

LED lead but that would be 600 solders. Will avoid if possible.

So purchased the Amphenol hoping to get an easier more, solid

connection at the LED, like the connx at the terminal blocks,

which are pretty easy, and very stable.

![[IMG] [IMG]](https://www.allenpitts.com/electronics/Matt_22_37/LED_to_PCB_Connx_190706_2_sm.jpg)

Hoped the Amphenol would solved the problem with fitting the header onto

the LED lead. But although the leads go into the header easier, the header

does not conduct through the LED to make the LED light.

See GIF marked LED Three.

Is there another lighting cable that would go from the

terminal blocks to the LED leads?

![[IMG] [IMG]](https://www.allenpitts.com/electronics/Matt_22_37/LED_to_PCB_Connx_190706_4_sm.jpg)

Thanks.

Allen Pitts, Dallas Texas