mojozoom

Member

My old car uses a 1mA current driven tach movement and the stock circuit isn't compatible with the MSD ignition box I use, and the adapter they sell to make the tach work buzzes like the dickens.

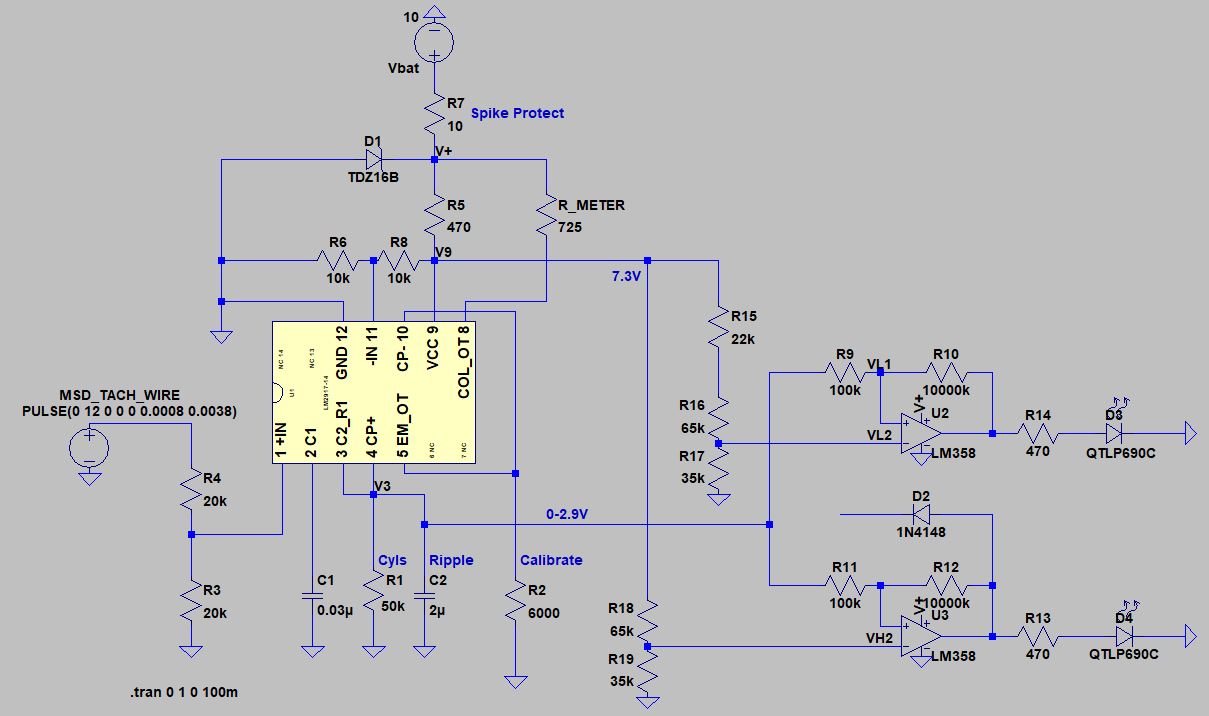

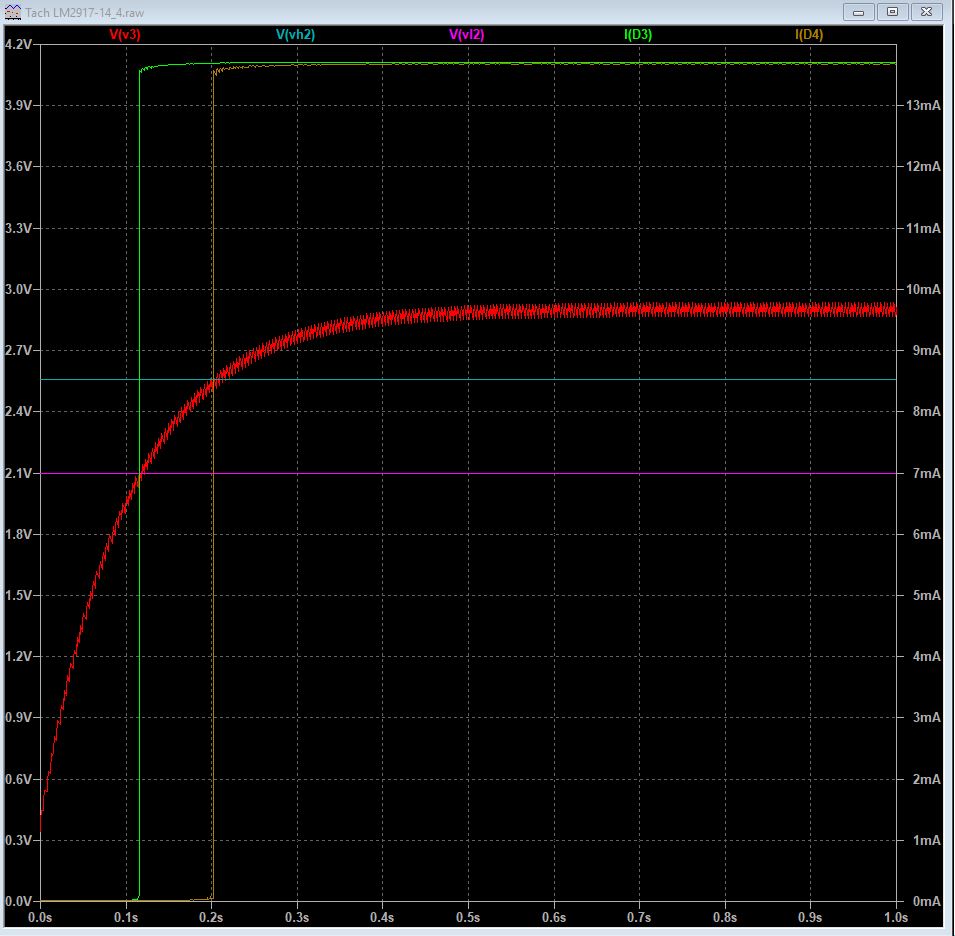

So I worked up a tach circuit based on the current tach diagrams in the LM2907 datasheet that'll work off the nice 12V square wave tach output connection that MSD provides. To go along with that I'd like to include a 2 stage shift light that lights 2 separate leds at a 400 rpm interval, and when the second led lights I'd like the first to go off.

I've got that that all worked up using an LM358 as a comparator, but I'm stuck using two pots and I really don't need independent adjustment of the two shift light turn on points - making them fixed at 400 rpm apart would be fine and hopefully minimize components. I was trying to use a voltage divider to fix two reference voltages and compare those to the tach output voltage, but everything I try seems to either work backwards or pulls down the current that the LM2907 is sending to the tach movement.

Can someone with more experience in these topics please advise if they see a better way to do this? Here's the circuit - ignore diode D2 hanging in the breeze there as it's just like that for troubleshooting. It connects to the - input of U2 above it in order to turn off the first led when the second turns on.

Thanks!

So I worked up a tach circuit based on the current tach diagrams in the LM2907 datasheet that'll work off the nice 12V square wave tach output connection that MSD provides. To go along with that I'd like to include a 2 stage shift light that lights 2 separate leds at a 400 rpm interval, and when the second led lights I'd like the first to go off.

I've got that that all worked up using an LM358 as a comparator, but I'm stuck using two pots and I really don't need independent adjustment of the two shift light turn on points - making them fixed at 400 rpm apart would be fine and hopefully minimize components. I was trying to use a voltage divider to fix two reference voltages and compare those to the tach output voltage, but everything I try seems to either work backwards or pulls down the current that the LM2907 is sending to the tach movement.

Can someone with more experience in these topics please advise if they see a better way to do this? Here's the circuit - ignore diode D2 hanging in the breeze there as it's just like that for troubleshooting. It connects to the - input of U2 above it in order to turn off the first led when the second turns on.

Thanks!