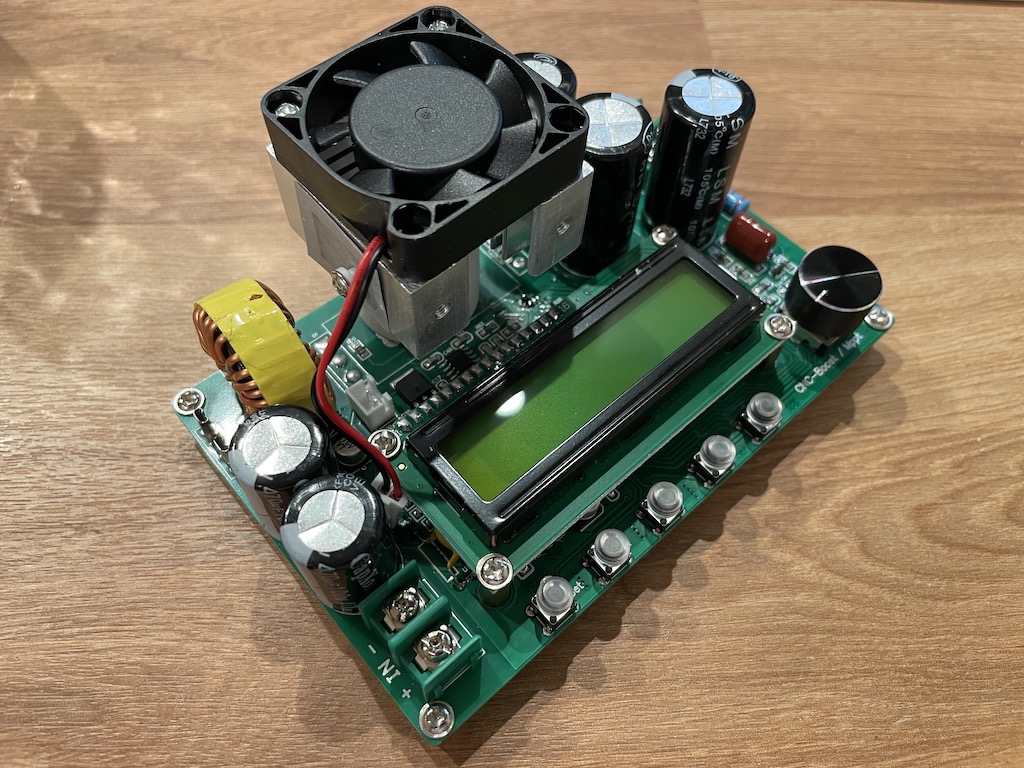

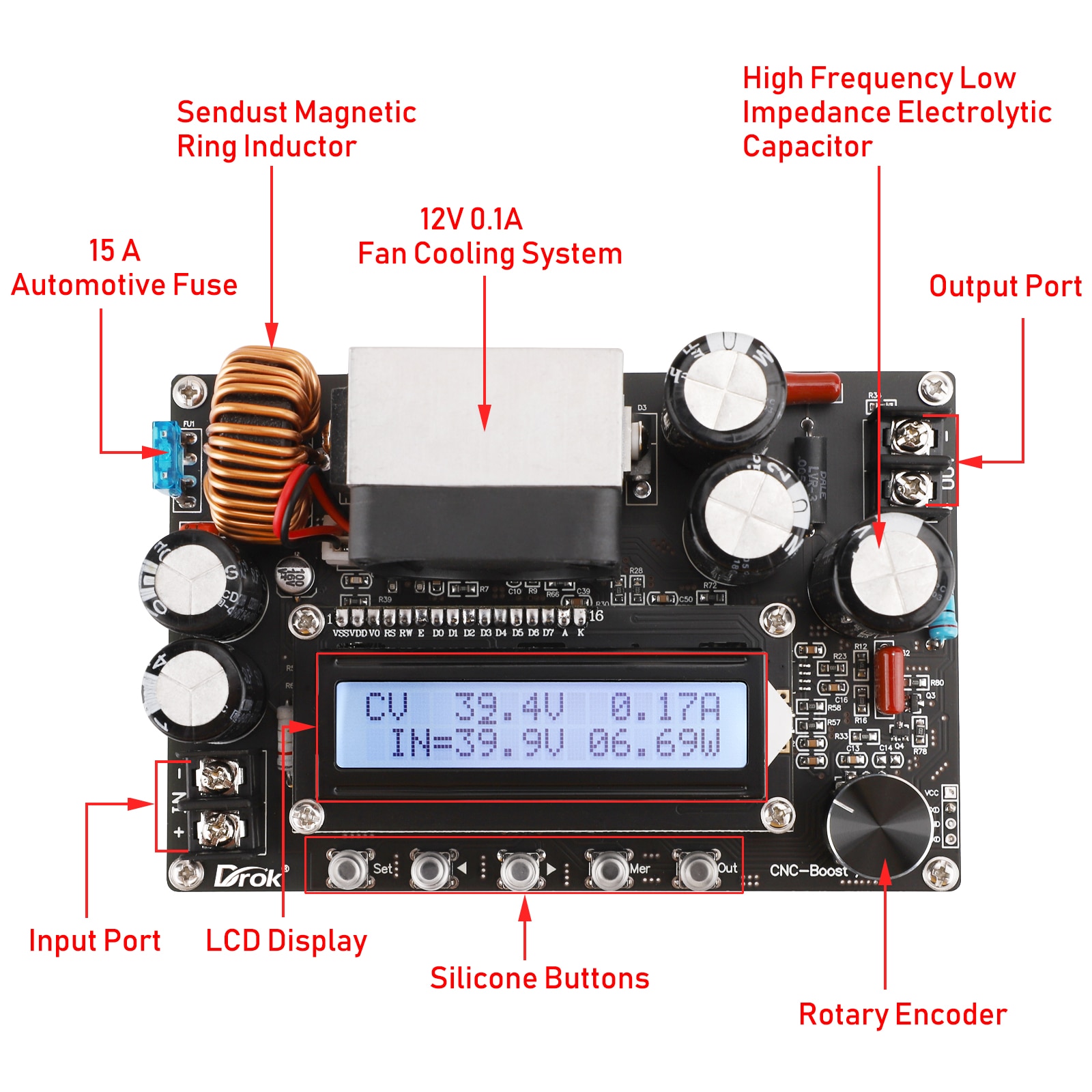

I use these AliExpress boost converters to charge batteries but I would like to make it function closer to its rated specifications. At the moment it gets really hot when at around 70% of its max rated load. I have tried replacing the fan with one that has a higher static pressure rating and it helped considerably but I was thinking I could take it further by adding a larger heatsink and another FET in parallel. Is it possible to add an identical FET in parallel to this pre made boost converter? It currently uses a 055N15A but If possible I would replace it with 2x IRFP4568. I know that the total heat will equal roughly the same but I am more concerned the thermal path being larger and the heat being shared across two packages. I am a complete beginner when it comes to electronics so please forgive me if this is a stupid question.