Hi spec,

My understanding is that the motor / wheel units are identical. So the wheel on the right hand side of the car will need to rotate clockwise for the car to move forward. (Looking at it from the outside of the car.) The wheel on the left side of the car will need to rotate anti clockwise for the car to move forward. So the polarity will need to be reversed to one motor.

Thanks Les,

I was really bugging me that you would have one motor going one way and another motor going another way. I was imagining the kind of steering that tracked vehicles have. Or that one motor was for forward and one motor for reverse. But now that you have explained it clearly the penny has dropped.

My thinking on the control side was to just use a microcontroller driving a logic level power mosfet. The ramp could be implemented in software and a PWM output could drive the mosfet. A simplified version of the table speed controller that I use on my milling machine would do the job. It uses a PIC16F876A. As it is it uses tacho feedback with a PID algorithm and the PID gain constants can be configured using a serial terminal. (I also have an unfinished version of the software to run on a PIC18F2431).

That would be a perfect approach but we do not know if the OP would be happy with a microcontroller approach.

Just a word about the requirement for a soft start using electric motors:

A stationary motor has no opposing EMF, so at the instant of turn on a huge current flows, limited only by the series resistance of the motor coils. This high current generates a high initial torque which results in the initial jolt and fast acceleration until equilibrium is attained and the current settles down to normal (for a given load).

Moving on to the load. To get a mechanical system moving you need to overcome, both stiction and inertia. So even for a progressive acceleration you do need an initial jolt of current.

If you feed a motor with a voltage ramp the motor will tend to just sit there until its torque is sufficient to overcome stiction and inertia and it will still start with a jolt or worse. This will vary according to prevailing conditions. Mind you is this case the motors are probably geared right down down so that will tend to limit the stiction and inertia efffects.

As I see it there are three general approaches to the problem.

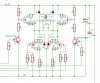

(1) your microcontroller PWM approach using a microcontroller.

(2) PWM approach using a 555 timer for example

(3) My constant current approach using two transistors.

Of the three options, from a performance aspect (1) has it

From an absolute simplicity aspect (3) has it.

And (2) probably has the best compromise between the two.

Just my view.

spec

. I need help with a soft start controller to prevent the jumping that her electric car does when she drives it... at 5 years, she's afraid to use it because of the jumping(in either direction). a adjustable ramp up speed would be helpful.. Two seperate timer circuits with diodes to select for forward or reverse?

. I need help with a soft start controller to prevent the jumping that her electric car does when she drives it... at 5 years, she's afraid to use it because of the jumping(in either direction). a adjustable ramp up speed would be helpful.. Two seperate timer circuits with diodes to select for forward or reverse?