Hello, I am working at a Arduino soldering station which use a PID controller.

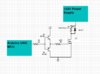

Please find attached the schematic and the code.

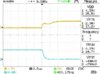

I have also attached screenshots from the oscilloscope. The blue trace shows the Drain signal and the yellow trace shows the G signal.

The mosfet used is a K1257.

I need support in finding if it is better to use a push pull circuit for controlling the mosfet. Please let me know if the push pull circuit is better for controlling the mosfet instead of directly controlling from the Arduino MCU.

Please find attached the schematic and the code.

I have also attached screenshots from the oscilloscope. The blue trace shows the Drain signal and the yellow trace shows the G signal.

The mosfet used is a K1257.

I need support in finding if it is better to use a push pull circuit for controlling the mosfet. Please let me know if the push pull circuit is better for controlling the mosfet instead of directly controlling from the Arduino MCU.