PackardDon

New Member

First just let me say hello and thank you for allowing me to be a part of this forum. To clarify, I am not an electronics engineer and know only the basics of electronic components but not the details needed for this project. Please be gentle with me!

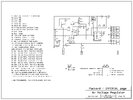

That said, I am working on a design for a voltage regulator for my vintage cars and I am hoping there is someone here with the skills to look over the schematic to see if it will work before I actually build it. A friend says it "makes sense" now after some errors the first few times but he was vague about whether it is something to be built or if more needs to be corrected.

This schematic is negative ground but is switchable from 6v to 12v and I will build it this way first but I also need it converted to positive ground or, better yet, switchable to positive ground. Can anyone help with any of these things? The design here should put out about 40A so is for larger charging systems than most I've found here and elsewhere.

That said, I am working on a design for a voltage regulator for my vintage cars and I am hoping there is someone here with the skills to look over the schematic to see if it will work before I actually build it. A friend says it "makes sense" now after some errors the first few times but he was vague about whether it is something to be built or if more needs to be corrected.

This schematic is negative ground but is switchable from 6v to 12v and I will build it this way first but I also need it converted to positive ground or, better yet, switchable to positive ground. Can anyone help with any of these things? The design here should put out about 40A so is for larger charging systems than most I've found here and elsewhere.

Attachments

Last edited: