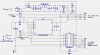

Attached is a schematic for a unipolar stepper motor controller using an 08M2. It has a built in 5V power supply that uses the 12V stepper motor power source as its input. It is designed to control the stepper motor either (a) via programming completely contained within the 08M2, or (b) via simpler programming contained within the 08M2 that is controlled by external circuitry. The external circuity could be another PICAXE that simply sends high signals on the input lines, or switch/relay contact closures that switch the 5V back to the 08M2.

Comments and suggestions are wanted. (I posted this on the PICAXE forum, but didn't get much response.)

Thanks.

Comments and suggestions are wanted. (I posted this on the PICAXE forum, but didn't get much response.)

Thanks.