Hi,

I've learned that UV tubes has a expire date. They say that after some time the UV rays start to fade.

Will this be the same for UV led's or does they last fore ever or for at least the time a normal led last.

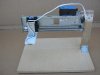

My second question is, if you want to replace your tubes with UV led's how many do you need for pcb's up to a size of say 200mm x200mm and how far from each other do you space them.

My last question is, what foreward current would you shoose to run them on. Will 20mA be ok?

I'll appresiate any help i can get.

I've learned that UV tubes has a expire date. They say that after some time the UV rays start to fade.

Will this be the same for UV led's or does they last fore ever or for at least the time a normal led last.

My second question is, if you want to replace your tubes with UV led's how many do you need for pcb's up to a size of say 200mm x200mm and how far from each other do you space them.

My last question is, what foreward current would you shoose to run them on. Will 20mA be ok?

I'll appresiate any help i can get.