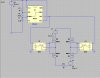

I want to connect two batteries in parallel using MOSFETs.

The condition is that the batteries must not be connected at all when the MOSFETs are open. I am aware of that relays can be used to, but out of curiosity i wonder if there is a clever way to do this with MOSFETs (switching speed will be higher than what relays can do also)

The thing that boggles my mind is that the source of the MOSFET can not be grounded and there is no single-directional current flow, so i am having difficulties creating the conditions to operate the MOSFETs as switches (Gate to source voltage difference)

Any ideas would be greatly appreciated

The condition is that the batteries must not be connected at all when the MOSFETs are open. I am aware of that relays can be used to, but out of curiosity i wonder if there is a clever way to do this with MOSFETs (switching speed will be higher than what relays can do also)

The thing that boggles my mind is that the source of the MOSFET can not be grounded and there is no single-directional current flow, so i am having difficulties creating the conditions to operate the MOSFETs as switches (Gate to source voltage difference)

Any ideas would be greatly appreciated