Gregory

Member

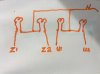

I have to replace a new motor on my milling machine.Single phase cap run cap start. Forward and reverse.

There is 4 wires 2 red 2 black.

How do I connect the wires into the motor with cap run cap start for forward and reverse.

There is 4 wires 2 red 2 black.

How do I connect the wires into the motor with cap run cap start for forward and reverse.

Attachments

-

C202AC0A-81AE-4C7E-8A8B-1A944799D235.jpeg1.2 MB · Views: 22,724

C202AC0A-81AE-4C7E-8A8B-1A944799D235.jpeg1.2 MB · Views: 22,724 -

44D2E4F1-C73B-456C-81C2-2500C01F9AC8.jpeg1.1 MB · Views: 17,934

44D2E4F1-C73B-456C-81C2-2500C01F9AC8.jpeg1.1 MB · Views: 17,934 -

F35470F8-BB7B-4BE3-BE86-C93A0FA1F82C.jpeg731 KB · Views: 2,779

F35470F8-BB7B-4BE3-BE86-C93A0FA1F82C.jpeg731 KB · Views: 2,779 -

9A76D468-8410-4A72-8CC2-A50224540F30.jpeg709 KB · Views: 2,838

9A76D468-8410-4A72-8CC2-A50224540F30.jpeg709 KB · Views: 2,838 -

413EB005-32D9-49BD-B90F-B675E2A96462.jpeg989.4 KB · Views: 1,090

413EB005-32D9-49BD-B90F-B675E2A96462.jpeg989.4 KB · Views: 1,090 -

45C1E483-561A-42AE-B12D-23DE7C058CDD.jpeg1.2 MB · Views: 1,602

45C1E483-561A-42AE-B12D-23DE7C058CDD.jpeg1.2 MB · Views: 1,602