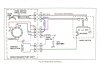

Windscreen wiper motor runs at 44rpm on 12v battery. This is too fast and want to reduce it to 1 to 5 RPM without using gears or pulleys?

I tried a cigarette lighter 12v to 1.5/9v reducer thingy but it obviously burnt out in 20 seconds.

Can it be done electronically, cheaply and 'oh so simply' explained?

Would I lose much torque if it could be done?

Cooking small joints of about 10kgs not huge great pigs of 70kgs.

I tried a cigarette lighter 12v to 1.5/9v reducer thingy but it obviously burnt out in 20 seconds.

Can it be done electronically, cheaply and 'oh so simply' explained?

Would I lose much torque if it could be done?

Cooking small joints of about 10kgs not huge great pigs of 70kgs.