MrDEB

Well-Known Member

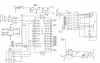

have a fairly simple project **broken link removed** that has the hex file and assembly file but having only worked with swordfish and junebug I need direction on programming a 16F88.

I at first contemplated using swordfish with LCD bas, SIP bas and ?? to read the temperature of the thermocouple.

The project uses a MAX6675 which needs a SIP routine which I understand is fairly easy but to a rookie yea right.

Looking at the code I have concerns that the LCD is using 4 bit code but not with the B ports in a row (B.0, B.1. B.2, B.3)

secondly the schematic shows LED resistors that calculate kinda hig for current but supposedly it works.

Just wish it utilized an 18F pic like a 1320.

Swordfish is sure easier to read.

If I can't get some sort of code then will go with the assenbly/hex file.

I at first contemplated using swordfish with LCD bas, SIP bas and ?? to read the temperature of the thermocouple.

The project uses a MAX6675 which needs a SIP routine which I understand is fairly easy but to a rookie yea right.

Looking at the code I have concerns that the LCD is using 4 bit code but not with the B ports in a row (B.0, B.1. B.2, B.3)

secondly the schematic shows LED resistors that calculate kinda hig for current but supposedly it works.

Just wish it utilized an 18F pic like a 1320.

Swordfish is sure easier to read.

If I can't get some sort of code then will go with the assenbly/hex file.