eimaj12000 said:

Just an update, I've checked everything again and still keep getting the same behaviour. Are there any glitches in the circuit diagram maybe ?

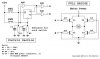

Yeah, there are glitches....although I'm confident its just the reset bit, and possibly the debounce part. Again, sorry for the changes, but its a case of 50% design and 50% 'tinkering' to get the values right.

I've attached yet another schem...I think if there are any more schematics to come, it would be wise to email you, don't wanna clog up this board with jpg's

Unfortunately, I do not have an AND gate to hand here, and substituting a 'NAND' gate with an inverter (same effect as an AND gate) isn't a perfect mach, because two gates are more sensitive to voltage changes.......but, I've tested the reset bit with both a CMOS inverter, and a transistor inverter and it works a treat. The only problem with this now is that the debounce circuit sometimes makes the circuit reset (well, its happened once so far).

So, I'd like to get a final design up that's reliable (in your circuit) and then we can worry about substituting parts in case you want to reduce the part count or 'add' things to it. This is an experience for me, although I'm 'ok' with logic, as far as I'm aware this sort of reset isn't used anywhere else...or the logic for that matter, as most just give up and go down the microcontroller route..but as I said before, unless you already have a micro, and a programmer (as well as all the software to support it) then its not always the easiest way.

<If this works>:

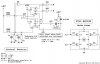

This version is simplified, but appears to produce a better 'reset' pulse. As for 'debounce', yes, inverters would be great. Use this little circuit for each switch once you have an inverter:

https://www.mikrocontroller.net/attachment/423/debounce.JPG

The part number '74HC14' isn't cmos...so for that you'll need either a 4069 (standard hex inverter) or a 4093 quad NAND. Now, because the second chip is a NAND and not a 'NOT' gate, you'll tie both inputs to the gate together, so it has one input and one output. You can google 'schmitt trigger' if you need to know what it does...in this application is would simply make things more reliable.

IF this works...then there are some clever tricks to reduce parts without comprimising on performance, so you'll have a smaller circuit.

Good luck,

BuriedCode.

Ps. Sorry again, I probably should have waited until I had a proper reliable circuit, tested at different power voltages before posting anything, but this seemed urgent so I waanted to keep you updated.

Edit:

Criticisms welcome by others....both FF's are meant to reset once BOTH siwtch are released (OR = 0) and although its not ideal...I can not think of a easier way to do this without bringing in many other (expensive) parts.

) ?

) ?