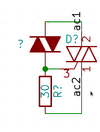

I've a over-voltage protection circuit for an inductive source which folds back the voltage above around 30V. It uses a diac and 1A rated triac (https://uk.rs-online.com/web/p/triacs/7271133?searchId=0aae111e-7ddf-4745-821c-b315d7ad716f) to do so. The inductive source is fixed current variable voltage at about 0.6A peak.

After a long time of operation handling an over-voltage condition the triac faults with the gate shorted at 0.6ohm to one of the legs (in the instance I tested ac1). Cascading, the diac becomes very hot on this half cycle but is saved by a tvs upstream, which burns and closes.

While operating correctly the triac is producing little heat, which is expected as it drops to around 1.3V, which at 0.6A until the AC cycle ends is about 0.78W dissipation. I've watched the triac on an IR scope and the heat build-up is little and so I don't think it's the problem.

Any triac experts out there?

After a long time of operation handling an over-voltage condition the triac faults with the gate shorted at 0.6ohm to one of the legs (in the instance I tested ac1). Cascading, the diac becomes very hot on this half cycle but is saved by a tvs upstream, which burns and closes.

While operating correctly the triac is producing little heat, which is expected as it drops to around 1.3V, which at 0.6A until the AC cycle ends is about 0.78W dissipation. I've watched the triac on an IR scope and the heat build-up is little and so I don't think it's the problem.

Any triac experts out there?